Tianda Chuzhou: a Breakthrough in Ultrasonic Inspection with Phased-Array Technology

Tianda Chuzhou performs the inspection on high-grade products with its new phased-array ultrasonic equipment, marking a significant breakthrough in detecting defects. This project, completed in record time, highlights cutting-edge strategy and effective technical collaboration between Vallourec and Wuhan Zhongke.

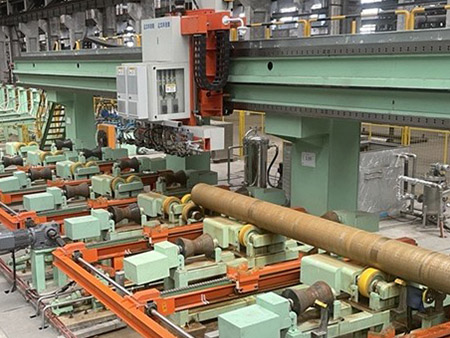

Vallourec Tianda Chuzhou has reached a crucial milestone with the introduction of its new phased-array ultrasonic production line, specifically designed to detect oblique defects in C90, T95, and C110 steels. This project, which meets the new API 5CT standard, represents a significant breakthrough for the company and its commitment to premium product quality.

Rigorous Supplier Selection

PC (Process Community)-NDT (Non-destructive testing) experts and the Tianda Chuzhou’s NDT team, fully supported by its executive team, took the decision to launch a new ultrasound project to meet current technical and regulatory challenges.

After evaluating factors related to technical difficulty, cost, project timeline and equipment maintenance, Wuhan Zhongke, a scientific and technological company and a non-destructive testing equipment manufacturer, was selected as the primary supplier.

Given the technical difficulty posed by the new phased array ultrasonic equipment, the project team took the initiative to schedule a meeting between the PC-NDT experts, the NDT team, Tianda Chuzhou’s Equipment Department, and Wuhan Zhongke to overcome these challenges.

Collaboration and Technical Problem Solving

During the acceptance phase at the supplier’s facility, Wuhan Zhongke faced major technical hurdles. Through close collaboration and rapid communication between the project team, the Group experts and Wuhan Zhongke’s R&D technical team, the issues were resolved, resulting in the project being completed in record time.

In December 2023, following a series of rigorous tests, including a plant acceptance test at the Wuhan Zhonghe plant undertaken by our Chinese NDT team, the equipment was installed and commissioned at Tianda Chuzhou’s Quality Inspection Workshop 140. The equipment’s performance indicators finally met the technical requirements, as confirmed by Michel Vahé, the EH region’s NDT expert, in February 2024.

At the end of April, the project steering committee met and unanimously decided that all performance indicators for the new phased array ultrasonic equipment met requirements, and that the on-site acceptance test had been successfully passed.

A Successful Localisation Strategy

Completing this project in just 15 months, compared with the usual 24 months for similar projects, is a remarkable example of Tianda’s capacity to manage large-scale projects. This achievement also underscores the success of the company’s localisation strategy for ultrasonic equipment and spare parts, reducing costs and enhancing long-term maintenance.

Towards Long-Term Collaboration

The success of this project paves the way for bolstered collaboration with Wuhan Zhongke for developing other essential spare parts and maintenance services for Tianda Chuzhou, as well as for the Group as a whole. The equipment provided matches the performance of industry giants like General Electric and Olympus, while offering significant advantages in cost and project cycle.

Strategic Advancement in Ultrasonic Inspection

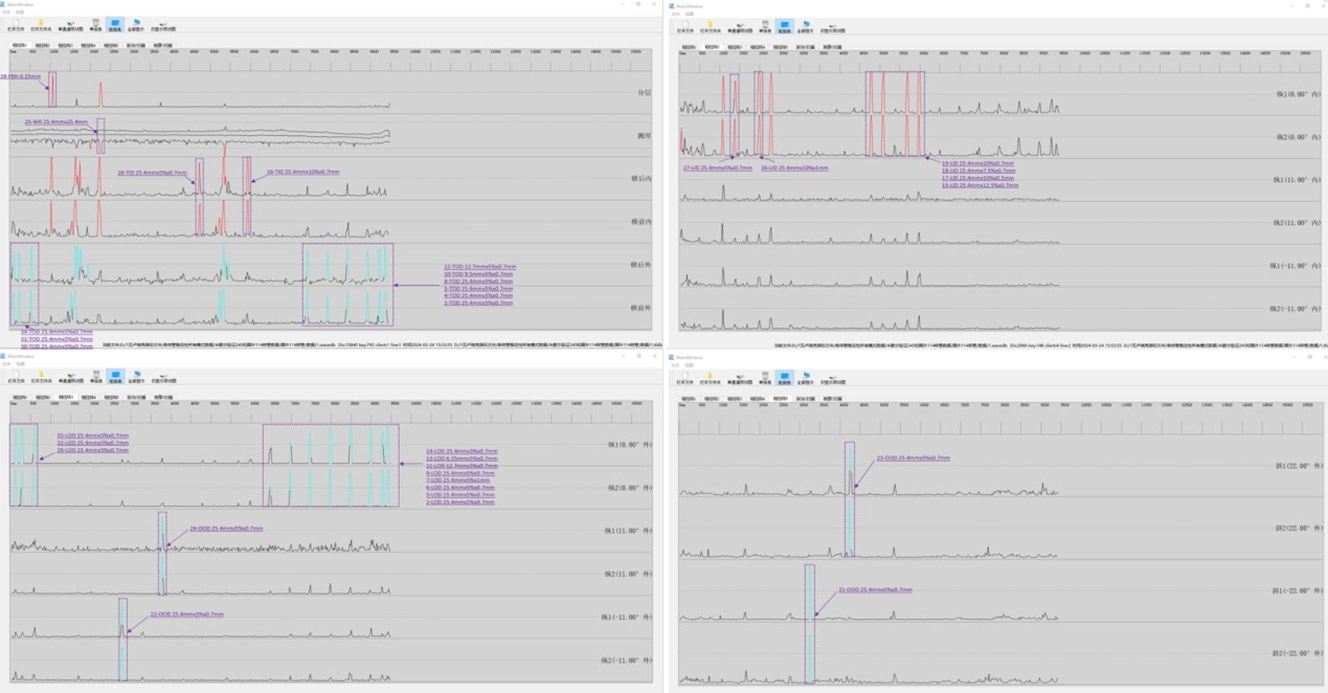

The successful acceptance of this equipment marks an important step in Tianda’s premium strategy. The phased-array technology allows for precise detection of diagonal defects, defect detection coupling monitoring, and thickness measurement, meeting the stringent requirements of high-end clients such as TotalEnergies.

The equipment is currently being optimised and is preparing to face future challenges in its best possible condition. This breakthrough strengthens Tianda’s position as a leader in ultrasonic inspection and demonstrates its commitment to industrial excellence.

Key Features of Phased-Array Inspection

- Oblique Flaw Detection: Precise identification of anomalies in C90, T95, and C110 steels.

- World-Class Performance: Comparable to equipment from General Electric and Olympus.

- Cost and Maintenance Advantages: Cost reduction and improved maintenance through local collaboration.

Contact: For more information visit our China website