Vallourec’s Role in Designing Safe CO2 Storage Projects

On April 7, 2022, Vallourec and World Oil held a live webcast showcasing how Vallourec leverages its expertise in tubular solutions to address the challenge of carbon capture and storage (CCS). Diana Rodriguez Barrera, CCUS Marketing & Development Manager and Cécile Millet, Head of OCTG Material Development and Application Research Center, discuss how Vallourec supports clients with material and connections selection for CCS projects. The webcast was a great success, drawing 211 participants globally. In this article, we look at the key messages and insights gleaned from the webcast.

From capture and transport to injection and storage, Vallourec’s expertise encompasses every stage in the CO2 lifecycle, supporting industry players as they deploy safe and reliable CCS infrastructure.

“CCS technology, deployed at a large scale, will play a key role in achieving net zero goals – but operators face several technical challenges,” Diana Rodriguez Barrera says.

Applying EOR expertise to CCS

CCS projects are diverse – and complex. CCS hubs take CO2 from multiple industrial sources, with varying impurities and concentrations in their CO2 streams. The Oil and Gas industry has more than 30 years’ enhanced oil recovery (EOR) experience that can be applied to CCS projects. However, the industrial CO2 stream contains a wide variety of impurities.

“In the more than 6,500 kilometers of pipeline currently serving the EOR industry in the US, the transported CO2 stream also contains methane, nitrogen, hydrogen sulfide and limited amounts of water and oxygen,” Diana says.

While there is no commonly accepted specification for transport by pipeline, experience has demonstrated that the combination of a relatively clean CO2 source and controlled water content limits operational issues. Since removing impurities from the CO2 stream increases a project’s cost, it’s crucial to choose the right materials and connections to withstand harsh environments.

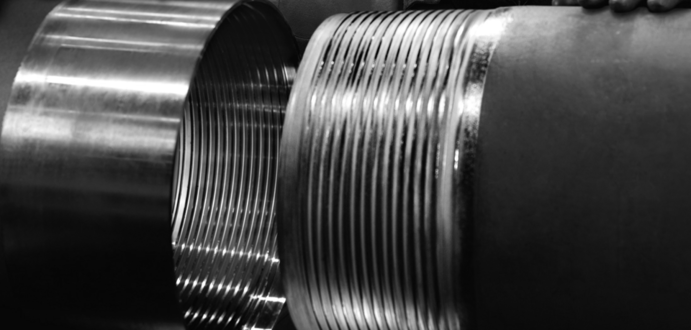

Highlighting Vallourec’s material and connections testing

Evaluating the performance of materials and connections in CCS conditions is essential to ensuring the integrity of infrastructure. “We need to consider challenges throughout the CO2 value chain,” Cécile Millet says.

The presenters discussed several key tests conducted by Vallourec experts that have helped shape the Group’s expertise and offer in this market:

- Vallourec performed tests on X60Q materials to determine resistance to hydrogen-induced cracking (HIC) at very low pH. Conducted at ambient temperature using hydrochloric acid, the results showed no blisters or HIC cracks after 96 hours.

- Teams tested material resistance to localized corrosion at the bottom of wells, where formation water is likely to collect during storage. Different materials were tested in different environments with varying levels of impurities: low-alloyed carbon steel, 13% chromium steel, super duplex 25% chromium steel and 28Cr steel. Results revealed that super 13 chromium is a cost-effective solution in the presence of limited oxygen.

- Vallourec tested material toughness by performing impact tests on carbon steel, duplex and super duplex materials. The material’s ability to absorb energy is the key to ensuring sustained performance at low temperatures. All carbon steel materials exhibited good toughness above 50 joules at -60°C, while duplex and super duplex are borderline materials especially for high strength materials. According to existing O&G standards, all Vallourec materials exhibit good material toughness properties.

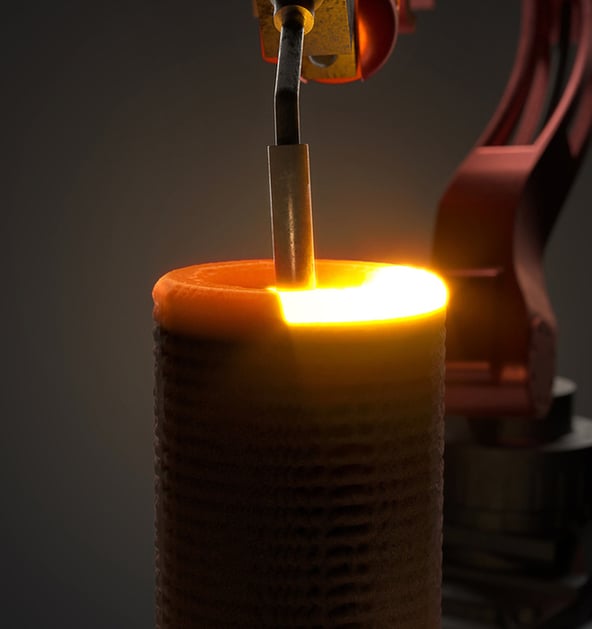

- Vallourec assessed its VAM® connections to ensure suitability for carbon capture, utilization and storage (CCUS) projects. To eliminate CO2 leaks, it is critical to guarantee sealability at low temperatures between the connections that join the tubing strings. Vallourec’s testing protocol is based on API-5C5 and includes three stages tailored to CCS applications that mirror the conditions the CO2 injection wells will withstand during their life:

1) tightness testing in low-temperature cycles

2) thermal shock at -80°C

3) temperature delta between the pin and the box

To choose the right connection and define sufficient working envelops, FEA studies were conducted. We evaluated surface treatment at extremely low temperatures to ensure there were no signs of fretting during cyclic operations. We also conducted surface treatment corrosion assessment using CO2. Results showed that Vallourec’s VAM® premium connections are ready to perform under CCUS conditions.

Partnering with industries across the globe

Our research & development program works hand in hand with industry and clients. We built a connections qualification protocol in collaboration with a client in the North Sea, and developed the testing and qualification equipment, enabling us to meet emerging CCS needs. We are focused on testing our materials and connections in real-life scenarios and conditions required by the growing CCUS market.

Interested in support with material selection or connections consultation? Contact Diana Rodriguez Barrera or Cécile Millet today.