Webcast: Qualifying Vallourec’s Steel Pipes for Hydrogen Storage and Transportation

On November 10, 2022, Vallourec and World Oil held a live webcast exploring the benefits and challenges of using steel pipes for hydrogen storage and transportation. Laurent Delattre, Marketing and Development Manager for Hydrogen, and Florian Thébault, Principal Corrosion Engineer, discussed hydrogen embrittlement, Vallourec’s pipe testing methodologies, and its hydrogen-qualified products. The webcast was a great success, drawing 237 participants globally. In this article, we look at the key messages and insights gleaned from the webcast.

Hydrogen gas has long been making headlines as a carbon-free energy with the potential to lead the green energy transition. Reaching that goal, however, will require a significant ramp-up of infrastructure for hydrogen storage and transportation. And new assets that will be specifically designed and built for this purpose will incorporate steel materials into their make-up. Hydrogen, however, presents specific technical challenges for steel pipes, and thorough tests will need to be conducted before transport and storage pipes can be qualified for hydrogen.

Pipes lead with efficiency

The benefits of using pipelines for hydrogen transportation and storage abound. “From a technical standpoint, pipelines enable a higher energy flow than power lines,” Laurent Delattre explains.

“As production and use of hydrogen grows, repurposing existing steel pipelines will prove a cost-effective transportation and storage option. New pipelines can fill gaps as well, where existing pipelines aren’t available. Infrastructure development will take time, though.”

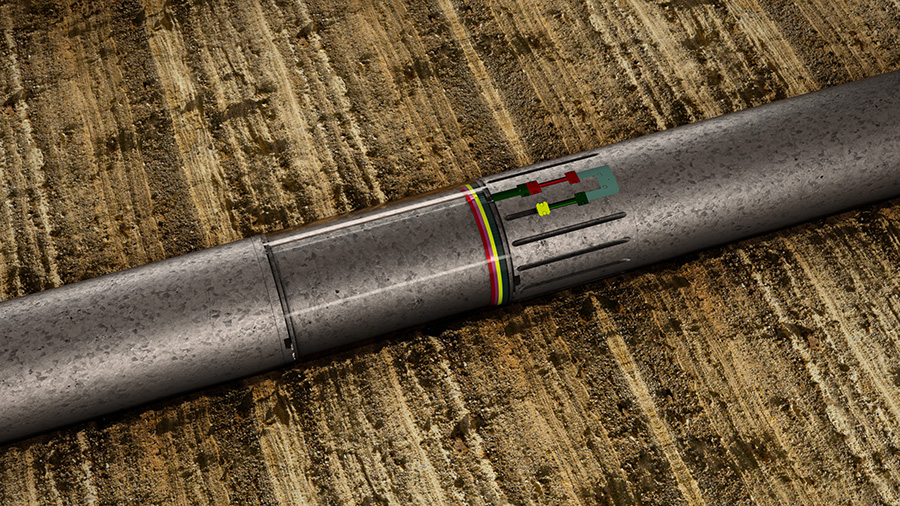

Similarly, robust hydrogen supply chains will require a lot of storage at different stages, and Vallourec is involved in a variety of storage solutions. “Cylinders are pressure vessel systems that can store hydrogen at very high pressures – typically holding up to a few tons of hydrogen,” Laurent says. “As such, they’re an excellent solution for hydrogen refueling stations. Pipe assemblies can storage larger amounts of hydrogen (1-10-100 tons), in vertical or horizontal configurations, and Vallourec is developing its solutions for this size of storages. And steel pipes and connections are already being used in the wells for underground salt caverns for long-term hydrogen storage.”

Safety is a key concern when dealing with hydrogen gas, which is both flammable and explosive. And not to mention the fact that it is also an indirect greenhouse gas. Threaded connections must be extremely tight to avoid hydrogen leaks. In addition, when used with hydrogen, steel used to build infrastructure must ensure a high level of safety and longevity

Technical challenges for hydrogen

Still, steel pipes designed to transport and store hydrogen must overcome several technical hurdles.

Hydrogen embrittlement – also called hydrogen-assisted cracking or hydrogen-stress cracking – is one such danger for steel pipes. “Hydrogen embrittlement occurs when hydrogen atoms are absorbed into steel and interact with dislocations generated by plastic strain,” Florian Thébault explains. “Hydrogen reduces the distance between dislocations and promotes their pile-up, leading to stress accumulation, and lowering the stress required for steel to crack. In the worst case, cracking can lead to hydrogen leaks, which present a major safety risk.”

Testing Vallourec’s steel pipes

The question, then, is how to test steel pipes for the ability to safely carry hydrogen. “Unfortunately, there are few standards to test against,” Florian says, “and there are many aspects of hydrogen stress cracking to evaluate. Steel composition, including hardness and microstructures, can affect cracking likelihood. Residual stress and geometrical imperfections in steel can do likewise. Environmental considerations matter as well, with engineers needing to account for factors like gas purity, temperature and pressure.”

To qualify its steel pipes for hydrogen transportation and storage, Vallourec used specific tests and protocols. “Our methodology looks at notched specimens, exploring the close interaction of absorbed hydrogen and steel materials,” Florian explains. “We worked with two different labs, which performed fracture toughness tests, using constant displacement to study crack initiation and crack arrest.”

Testing revealed that all Vallourec products were suitable for hydrogen storage, against ASME B31.21, an American pressure piping standard. And we were excited to see that testing results suggest that our steel pipes could be used even at higher hydrogen pressures

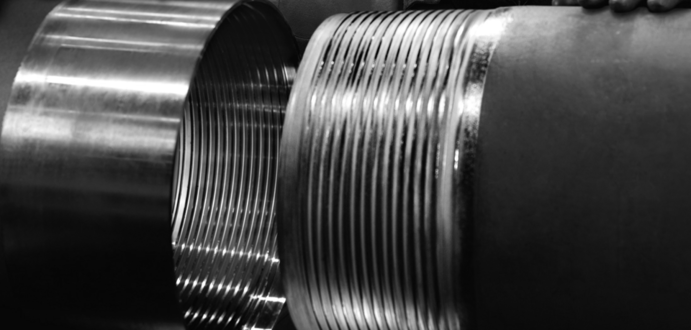

Our hydrogen-qualified products

Five Vallourec seamless materials were tested, including the X65 for linepipes, 3 OCTG grades – VM55W OCTG (weldable), K55 and VM80S (used with connected joints) – and the 34CrMo4 pressure vessel. This means a wide variety of microstructures and mechanical properties were tested. Three to five specimens per product were examined at each laboratory and evaluated for crack propagation after exposure to hydrogen gas.

“Based on these tests,” Laurent concludes, “we can be confident in the use of Vallourec steel grades for hydrogen infrastructure. And we have been able to demonstrate that our proprietary grade steel, such as VM80S, is optimized for performance, safety and integrity. This gives Vallourec a strong base for further steel pipe qualification, and can help us provide safe, efficient transport and storage solutions to customers developing hydrogen projects.”

Interested in learning more about pipeline qualification for hydrogen applications?

Contact Laurent Delattre or Florian Thébault