VAM® HTTC CLEANWELL®: successful first running in High Torque Liner applications in the Middle East

VAM® HTTC was successfully run with CLEANWELL® in a customer’s offshore and onshore fields in the Middle East, encompassing several types of applications from injector to producer wells including challenging Extended Reach Drilling designs. In total, over 1,500 joints, equivalent to more than 18km, have been used so far, which were successfully prepared and run in-hole with no rejects and presented remarkable stability during make-up.

Extreme High torque challenges

The operator’s offshore and onshore applications require extreme high torque and tight clearance connections especially in case of specific well designs with lateral strings over 20,000 ft for some. These are among the longest horizontal wells in the world with a recent record of 45,000ft drilled length. The operator’s highly technological completion plan can include several control devices and complex lower completion architecture accounting for over 20 different compartments in some cases.

VAM® HTTC and CLEANWELL®, a winning combination

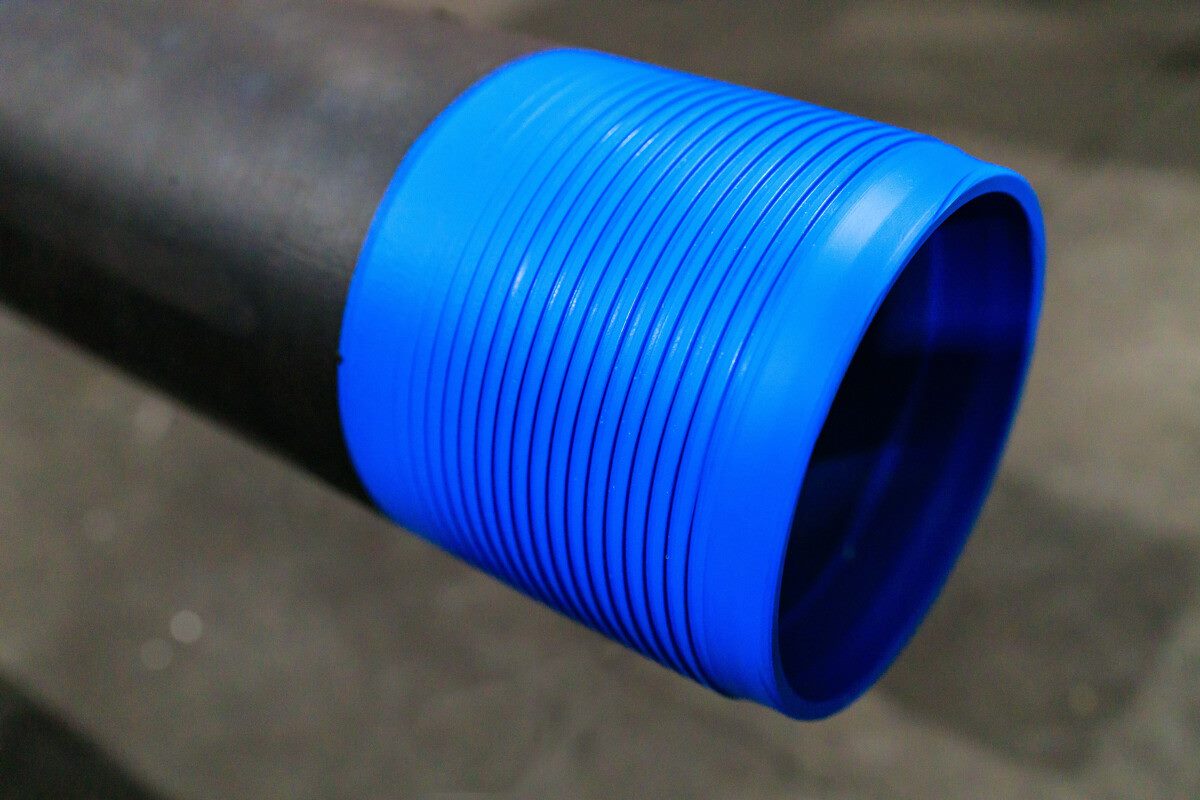

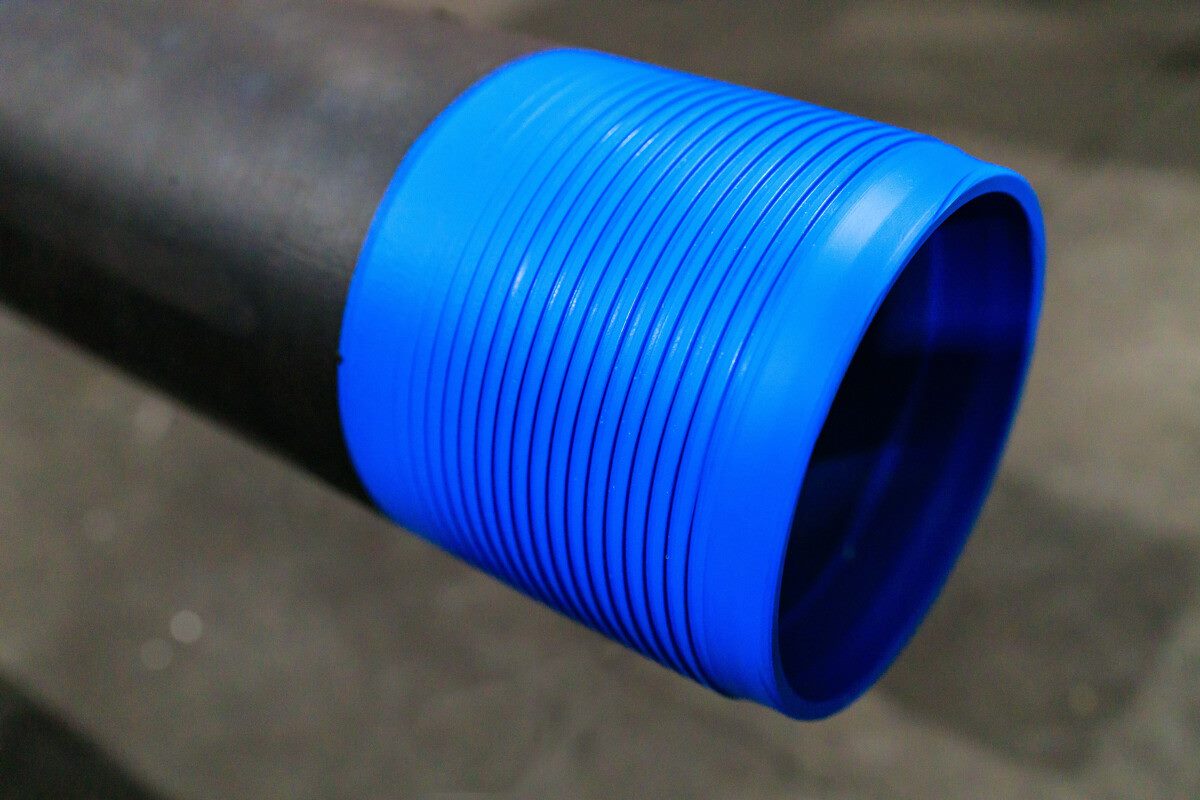

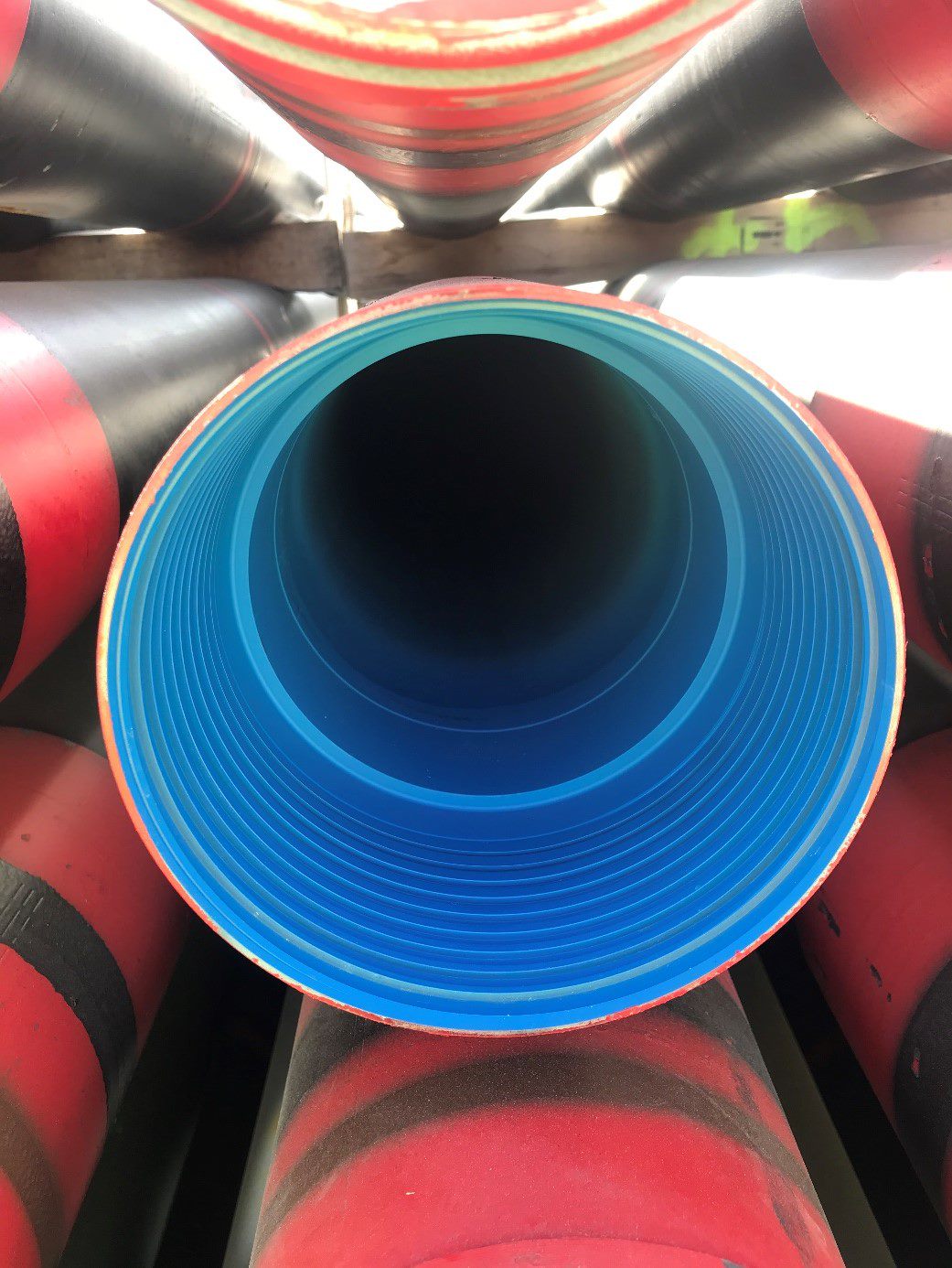

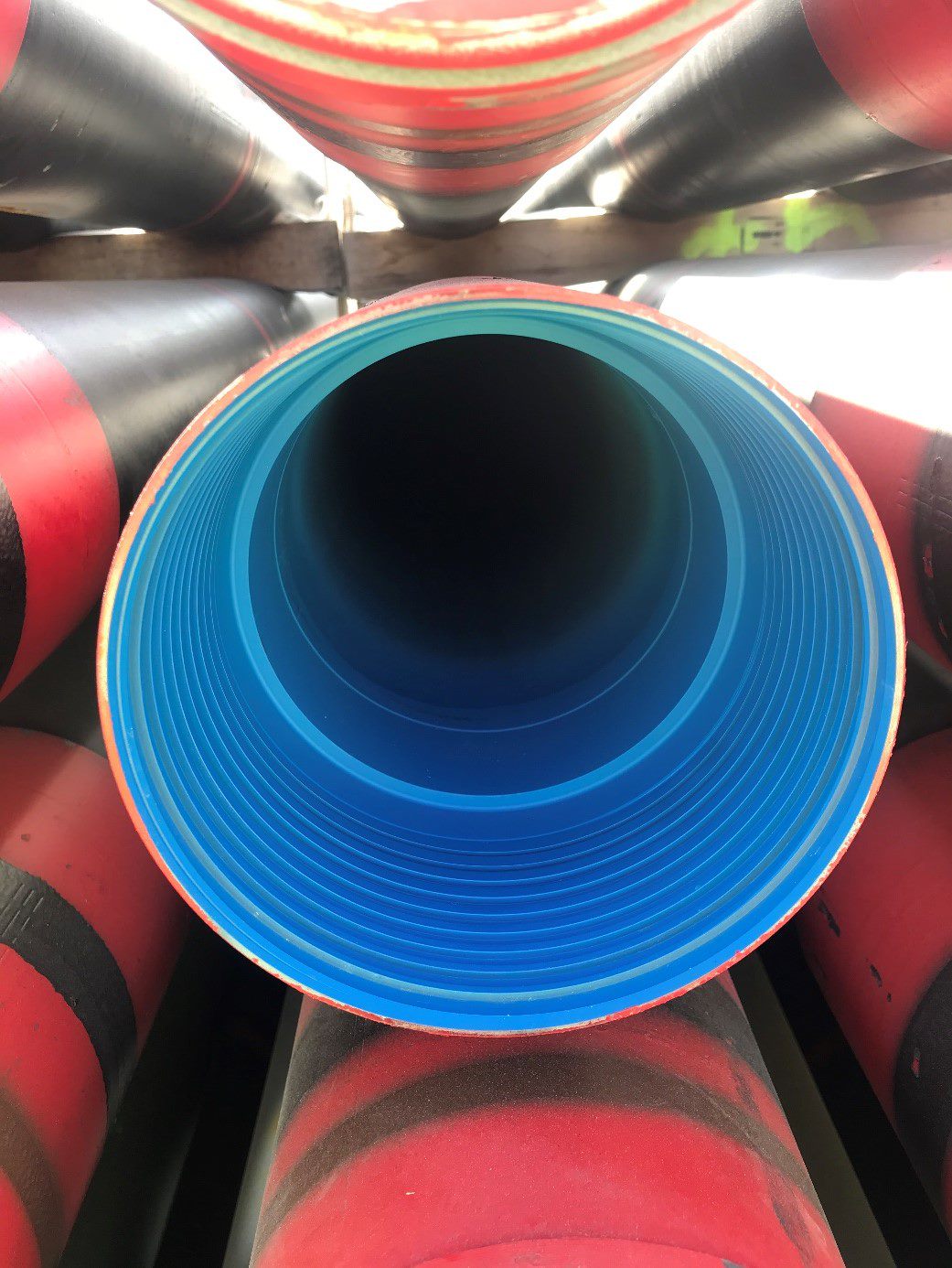

To meet such a challenging scenario and respect the customer’s specific requirements, Vallourec qualified its dope free solution, CLEANWELL®, on VAM® HTTC connections with Special Clearance. CLEANWELL® is a non-polluting coating applied in the mill to threaded connections replacing both storage and running compounds. The pipes were produced at Vallourec’s mill in France then stored and rig-prepped at Vallourec Tubular Services Abu Dhabi, Vallourec’s dedicated yard in the UAE.

The use of the CLEANWELL® increases efficiency by providing a “rig-ready” solution, reducing handling operations and associated HSE risks, and improving protection against corrosion and galling while avoiding environmental contamination due to compounds.

More than 1,500 joints of 6 5/8” 24 lb/ft L80 VAM® HTTC-NA SC73 CLEANWELL® were run in the operator’s offshore and onshore rigs. Vallourec’s fast and smooth preparation was mainly due to the absence of dope cleaning and re-application and zero rejects after storage thanks to its dope-free solution CLEANWELL®.

The pipes remained in storage for more than a year and showed no signs of deterioration when the protectors were removed. Pipe inspections held on the rig once again confirmed CLEANWELL®’s reliability. While meeting the customer’s requirements, CLEANWELL® also contributed to operational savings throughout the supply chain.

Improved operational efficiency and reduced environmental risks

The running performance was excellent. Assisted by dedicated running guidelines and VAM® Field Service support, the operations presented zero product-related rejects as well as a quick identification of make-up compliance supported by stable and repeatable graphs all throughout the job. The field teams who attended and monitored the operations, including customer representatives, acknowledged the robustness and contribution of the VAM® HTTC CLEANWELL® to the achievement of such good results.

“VAM® HTTC in combination with CLEANWELL® is an excellent product”, confirmed Steven Brown, VAM® Field Service technician supervising product running. “Easy to run, it saved us time during running, with very few breakouts while providing excellent gas tight sealing. We also appreciated CLEANWELL®’s environmental friendliness compared to traditional running thread compounds”.