Yellowtail line pipe project kicks off 10-year agreement between Vallourec and ExxonMobil in Guyana

In 2022, the 10-year Long-Term Agreement (LTA) between Vallourec and ExxonMobil Guyana began with the Yellowtail project. The customer will utilize Vallourec’s premium line pipe products and its suite of digital solutions.

Renan Toussaint, Line Pipe Project Manager, and Romain Nieddu, Line Pipe Project Quality Coordinator, talk about the project.

Yellowtail gets the first green light

Yellowtail is a deepwater project based in the Stabroek Block, over 100 miles off the coast of Guyana. In 2022, Vallourec produced 20,000 tons of line pipe for the Yellowtail project, equivalent to 7,000 pipes and 400 accessories. Oil production for the Yellowtail project is expected to begin in 2025.

“In order to deliver timely, quality products for the Yellowtail project, we are leveraging our pipe mills in Jeceaba and Barreiro, Brazil,” Renan explains. “We can also draw on our R&D program to further ensure customer demands are met.”

The right tools for the job at hand

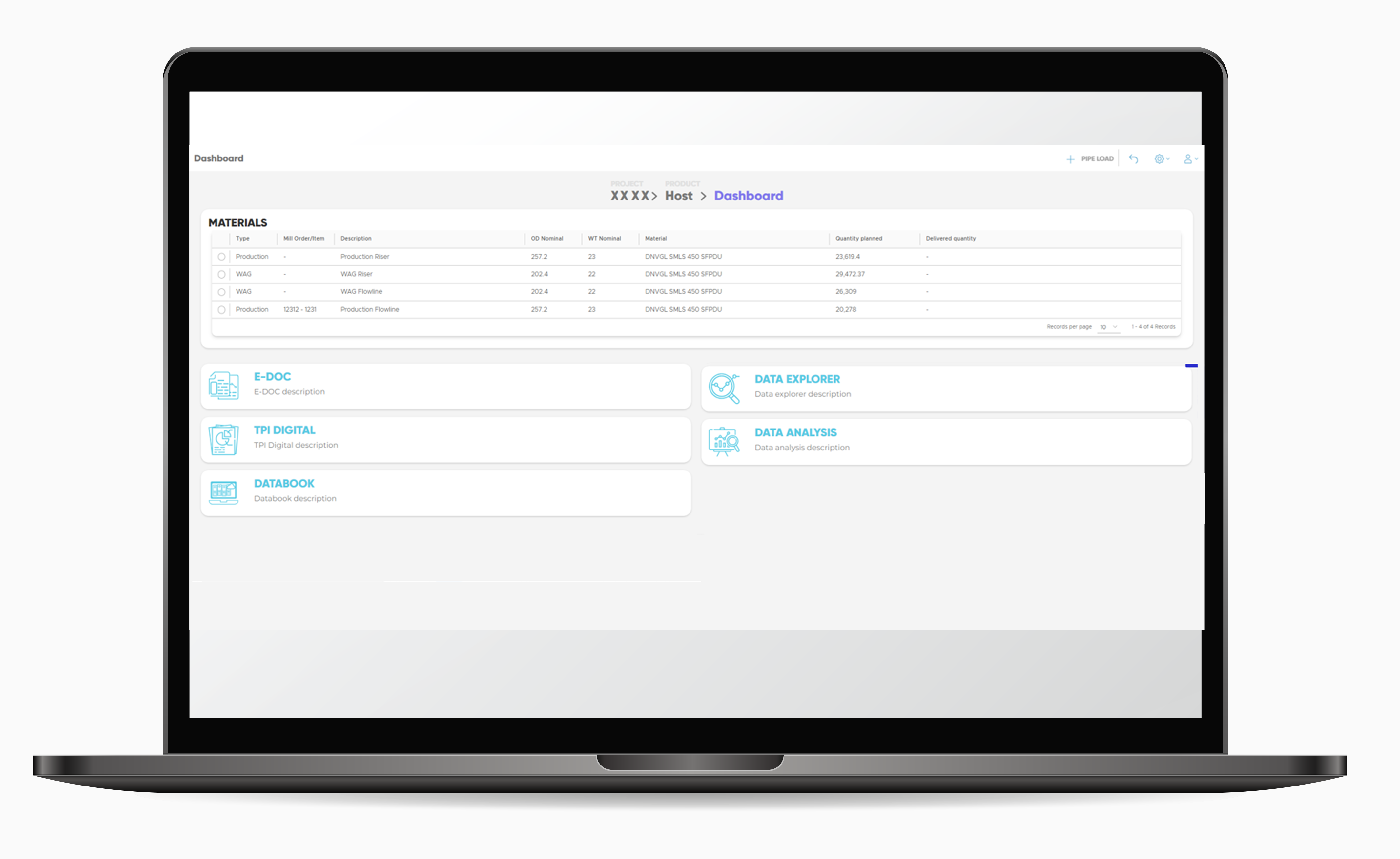

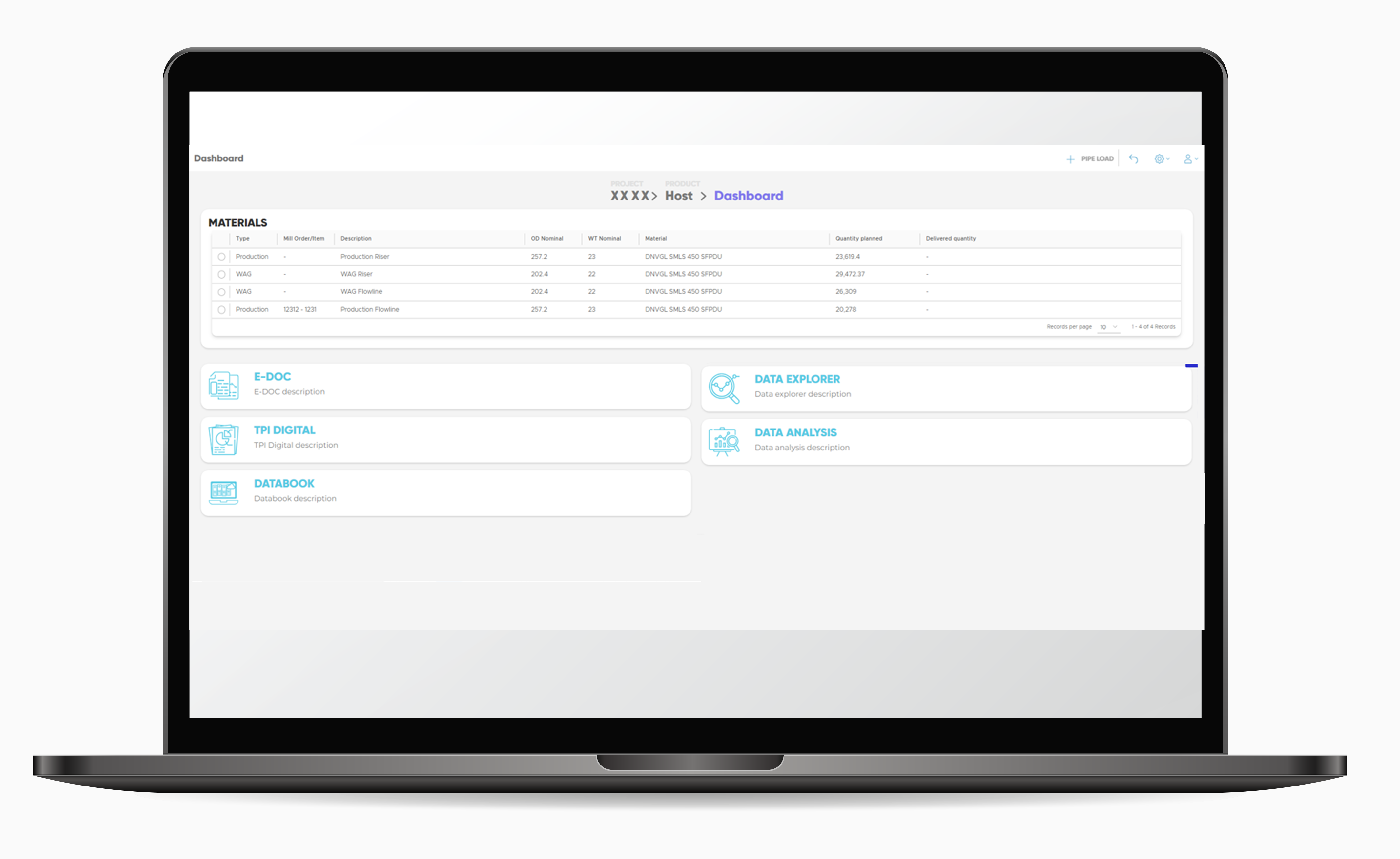

This project also represents a step forward for Vallourec in the use of digitalized tools at all levels of operations, from the production stage to customer operations. Vallourec’s ability to offer a complete package of both products and associated digital services is developing into a key factor for customers. ExxonMobil Guyana is leveraging several Vallourec tools, including Smartengo Traceability and Pipe Navigator as well as Best Fit analysis.

Pipe Navigator is a portal that provides a web interface for centralized data and document storage. “It strengthens and accelerates the quality review flow and gives live access to the entire production process,” Romain adds. “That level of transparency has really helped us build trust with our customers.”

Finally, Best Fit identifies pipe compatibility for pipe fit-up for girth welding, providing full visibility on achievable misalignment (Hi-Lo). “Thanks to Best Fit, the customer receives key information about pipe end tolerances and associated fit-up simulations for all possible pipe combination long before the start of operations. It allows them to better assess risks at an earlier stage and make decisions concerning critical sections such as fatigue-sensitive areas,” Renan says. “With this knowledge, our customer gets the most out of our pipes in terms of efficiency.”

Finding the way with Pipe Navigator

Pipe Navigator adds solid value for customers. “To help them see the value of this digital solution, our IT team will make adjustments to tailor it to their specific needs,” Romain says. “Customers can see the advantages of the online directory and the unique storage offer for contractual, project and production documentation."

“The data package benefits are clear,” he continues. “All the information that a client could want is in a single database, available at the touch of a button. For the Yellowtail order, there are 3,000 individual documents, so having them in an electronic format rather than paper is key. Document signature is also quicker and more efficient through the platform.”

ExxonMobil Guyana has included the use of Pipe Navigator on subsequent orders.

Vallourec’s LTA with ExxonMobil Guyana is underpinned by mutual collaboration to deliver projects in the Guyana portfolio. Special credit goes to Vallourec’s mill teams, for their work in adapting to customers’ requirements. “When working with digital tools, everything can change so fast,” Renan says, “so it is invaluable both internally and for the customer to work with teams that show both agility and a customer-centric attitude.”