A successful start for Vallourec’s CCUS testing methodology, and a step forward for the energy transition

Industries are increasingly looking to carbon capture, utilization and storage (CCUS) – the process of capturing carbon and injecting it into underground storage reservoirs – as a key way to advance the energy transition. However, while CCUS has strong potential as a long-term solution for decarbonization, no testing methodology or standards currently exist for assessing CCUS equipment. To bridge this gap, a team of Vallourec experts has begun developing a specific testing methodology for CCUS equipment and qualifying premium VAM® connections for use in the injection stage.

In late 2020, developers of a major European project for carbon capture and storage contacted Vallourec with an unusual question. How, they asked, would Vallourec’s signature VAM® connection perform in the low-temperature environment common to CCUS projects?

Addressing specific challenges for CCUS connections

Qualifying connections for CCUS applications requires different tests than those used on OCTG applications, due to the distinct conditions under which they must be able to function.

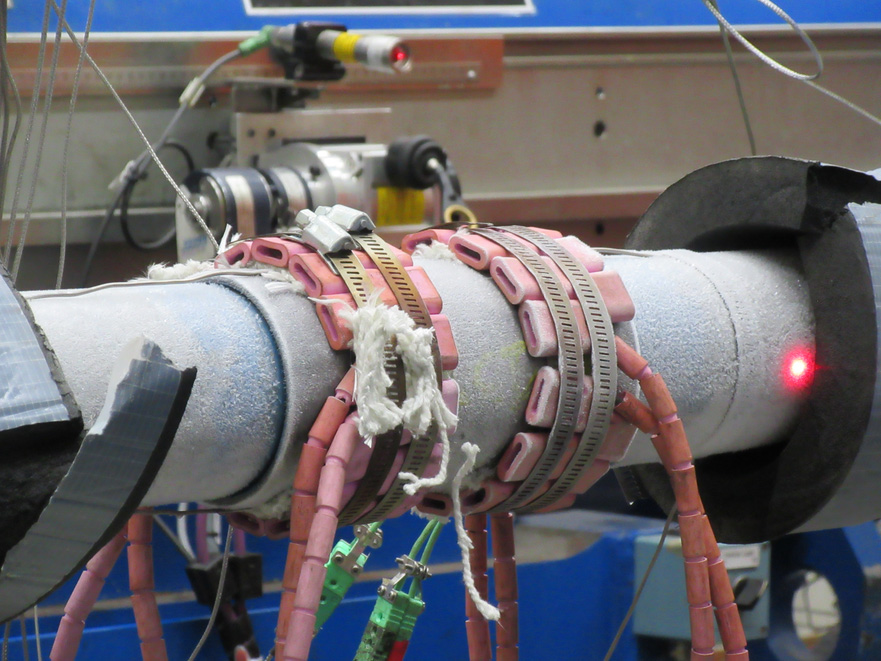

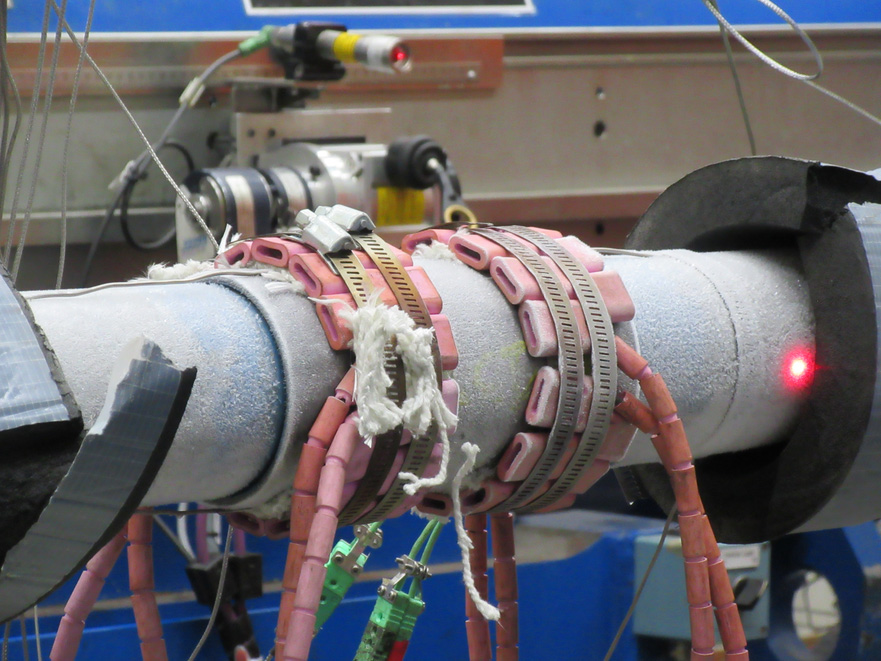

“Our first challenge was to understand how VAM® connections would behave at extremely low temperatures,” says Eric. “Our product is very reliable at high or ambient temperatures, but in CO2 applications, equipment can reach cryogenic temperatures as low as -80º C. We had to conduct a series of small-scale tests, assessing friction, and comparing lubricants to determine the levels of cold VAM® connections could withstand.”

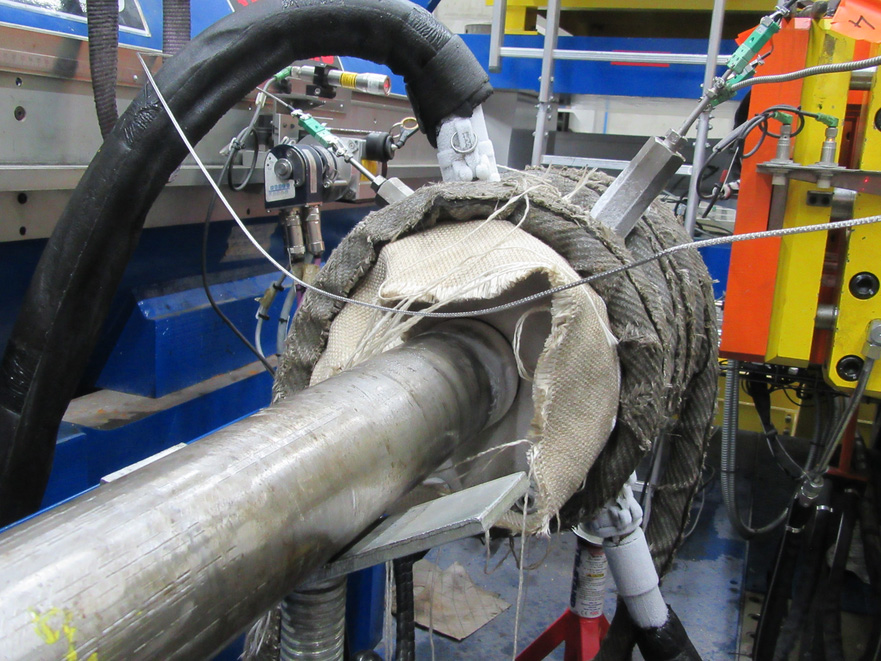

See on the left: Specific cold assembly

Next, Eric and his team needed to verify that VAM® connections would remain structurally sound and reliably sealed during thermal cycles. Dramatic drops in pressure and temperature can occur during CO2 injection, and this can weaken structural resistance and sealability, impacting both the equipment and surrounding environment. CO2 can be dangerous if not properly handled, so it vitally important for operators to follow the right steps and receive all qualifications for VAM® connections.

“For CCUS projects, operators inject CO2 mostly in a dense phase”, explains Ali Meschi Amoli, CCUS Marketing & Development Manager at Vallourec. “If for any reason there is a sudden release of pressure, this results in a major drop in temperature. We had to ensure that VAM® connections could handle this phenomenon –(known as thermal shock) – and verify that the box and pin would stay connected despite massive temperature differentials.”

Developing a cutting-edge testing protocol

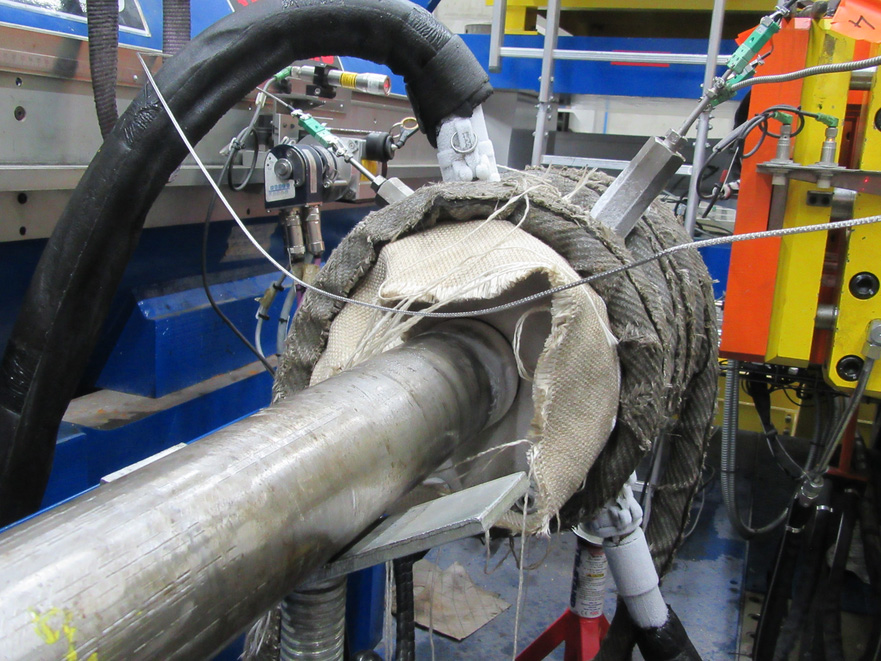

The team defined a five-stage testing method that would be sufficiently rigorous to verify VAM® connections’ safety and reliability. “We started by testing a standard loading cycle, just as we would do for an OCTG application,” says Pierre Martin, R&D Manager at VRCC.

On the right: Alternative assembly

Following several successful tests, the team expects to qualify VAM® connections for CO2 injection applications using their bespoke testing methodology by November 2021. This ambitious timeline serves to highlight the growing call for CCUS applications. “Our twin objectives are to offer clients a robust, expertly developed equipment testing protocol and safely adapt VAM® connections for use in CCUS projects,” Pierre continues. “To do this we are leaning on the expertise of eight internal experts and partnering with SINTEF Energy Research.”

Vallourec has already had several exchanges with SINTEF Energy Research, a renowned Norwegian Research and Development Organization with profound expertise in thermodynamics and the phase behavior of CO2. By partnering with SINTEF Energy Research, our experts are filling in knowledge gaps and gaining the insight that will help ensure the safety and reliability of VAM® connections for CCUS projects.

Playing a key role in the energy transition

This project includes experts from across Vallourec’s research centers (VRCC & VRCF) in France, and has been funded and developed in close collaboration with the Energy Transition department. “Vallourec has brought together top-notch expertise to develop a clear methodology for CCUS equipment qualification,” says Leila Faramarzi, CCUS Director at Vallourec. “This will be an indispensable support for our clients as they advance their decarbonization projects and accelerate the energy transition.”

On the left: Sample in the testing bench

While CCUS is still a developing industry, Vallourec is already providing technical support to several significant projects in Europe, the United States and the Middle East. “Our approach to this new industry is, as ever, thorough – we cut no corners and take no shortcuts,” Eric says. “Our goal is to deliver a rigorously vetted testing methodology used to qualify equipment that will perform reliably for decades.”

These initial tests – soon to be followed by more – put Vallourec on track to have a safe, qualified product for CO2 injection.