Energy transition: Vallourec takes part in Hywind Tampen project

Vallourec is partnering with Aker Solutions, an engineering company well-established in the global energy industry. As the provider of engineering, procurement and construction (EPC) services, Aker Solutions commissioned Vallourec to provide seamless hot formed hollow sections for Equinor’s Hywind Tampen floating wind project.

Hywind Tampen is an 88 MW floating wind power project intended to provide electricity for the Snorre and Gullfaks offshore field operations in the Norwegian North Sea. It will be the world’s first floating wind farm to power offshore oil and gas platforms.

For this cutting-edge project, Aker Solutions required pipe material direct from an approved and audited pipe manufacturer. Having already undergone mill and product auditing in 2014, Vallourec fit the bill. “Aker Solutions needed thirteen different pipe sizes for the various boat landings and service decks they were building, and we were able to meet that demand,” says Stephan Scherf, Sales Manager of Global On- and Offshore Construction Projects. “We had a good history of working together that established a foundation of trust at the outset.”

Supplying seamless technology

In total, Vallourec supplied 340 tons of seamless hot formed hollow sections in square, rectangular and round shapes, partly blasted and coated and in accordance with NORSOK standard M-120, Material Data Sheets Y27 and Y07. The Vallourec Plug Mill in Rath-Düsseldorf and the Continuous Mill in Mülheim produced the range of thirteen sizes needed for the project.

Vallourec’s structural steel grades are qualified to international offshore standards, and the Group’s seamless tubing technology ensures particularly high efficiency and quality.

“Our seamless hot formed hollow sections feature high static values, excellent surface behavior and extreme resilience. They also meet the quality requirements and safety standards set by Aker Solutions,” Stephan says.

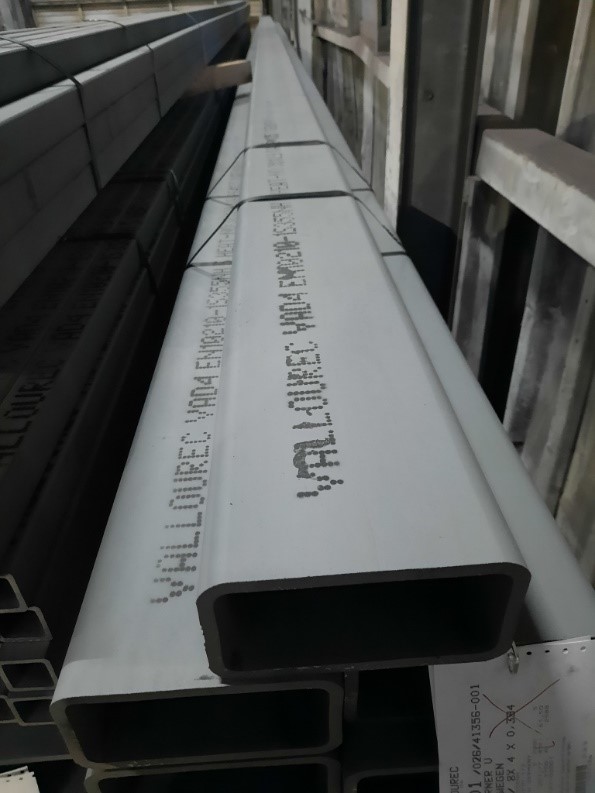

On the left: Seamless MSH blasted and primed, 200 x 100 x 10 mm

Added value with Vallourec

Aker Solutions saw our Group as an ideal partner for multiple reasons. Stephan explains: “They appreciate our product’s efficiency, weldability and robustness in sea conditions like waves, currents, corrosion and extreme temperatures. Aker Solutions opted for Vallourec because of our positive history of collaboration, the quality of our work and the fact that we are a global reference in offshore construction, especially in wind.”

Vallourec has already supplied over 20,000 tons of hot formed seamless hollow sections for offshore wind farm projects around the world. Vallourec’s transferable knowledge and expertise from past successes have helped streamline the whole supply chain, making a highly complex process run smoother.

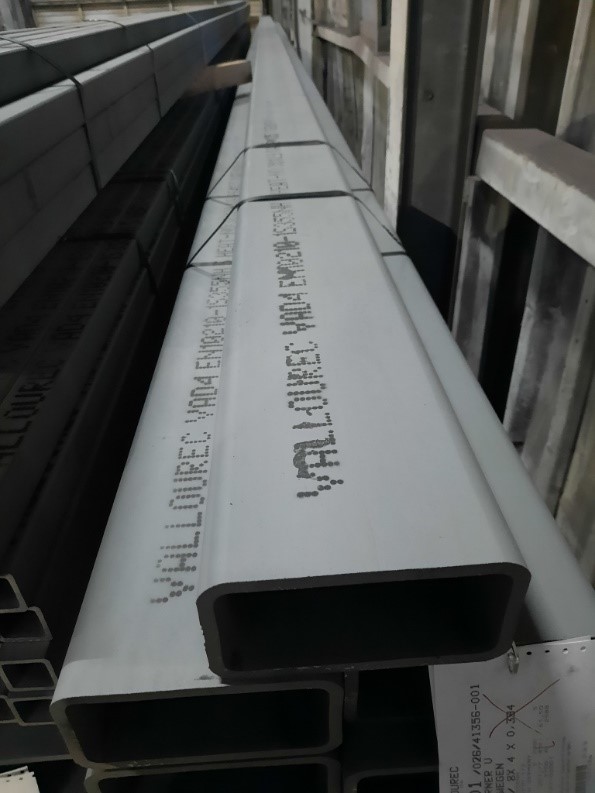

On the right: Seamless MSH blasted and primed, 50 x 50 x 5 mm

Positioning for a greener future

The Hywind Tampen project has strengthened our relationship with Aker Solutions, widely recognized as a major player in the booming offshore wind market. With around 2,400 wind turbines installed per year around the world, experts predict that cumulative capacity will reach 206 GW by 2030 (1). “This really shows that this segment will dramatically accelerate in the next few years,” Stephan says. “Hywind Tampen is a perfect reference to show the world that we can support future projects in this sector.”

This project aligns perfectly with the Group’s strategic roadmap, aimed at accelerating its commitment to the energy transition to meet customer needs while improving their CO2 emissions and environmental impact.

Indeed, as the transition to sustainable energy becomes increasingly important, the lessons and experience gleaned from Hywind Tampen will prove invaluable. Aker Solutions is currently participating in several big new offshore wind tenders for FEED and EPCI, including one with Vallourec. Independently, Vallourec is also bidding on several major projects for which it aims to supply offshore structural steel.

The Group is positioned to be one of the most attractive suppliers for dozens of new projects requiring several thousand tons of steel for wind farms worldwide. “It’s an exciting time,” Stephan says. “Floating wind is gaining momentum in the O&G industry, with which Vallourec has strong ties. Major O&G companies are investing in larger wind farms and moving toward this next frontier of renewable energy. Opportunity abounds for us in the US, Asia, Europe, and all around the world!”

(1) https://about.bnef.com/blog/annual-offshore-wind-installations-to-triple-this-decade/