Best to know before you drill: Actual pipe data from Prime Mapping service for highest downhole performance

Downhole operations can be complex. Operators deal with challenges ranging from cement displacement to packer setting issues and casing wear. To combat such problems, operators need access to complete pipe data that can help them identify issues before it occurs.

Until now, they have relied on nominal data – general information about a particular type of pipe. Meanwhile, manual calipers can measure pipes’ length and internal diameter (ID) but can’t perform full-length mapping. These existing solutions lack the accuracy and thoroughness that operators actually need.

Binh Nguyen, Project Manager at Vallourec, explains how Vallourec’s Prime Mapping service responds directly to customers’ needs, collecting actual pipe data in the field to simplify and improve operators’ downhole operations.

Prioritizing accuracy and safety while saving time and money

Drilling and completion aren’t an exact science. But with services like Prime Mapping from Vallourec, oil and gas operators can obtain precise actual pipe data that helps them drill faster and more reliably. “Our goal is to equip operators with the most accurate pipe measurements possible for their casing and tubing,” Binh explains.

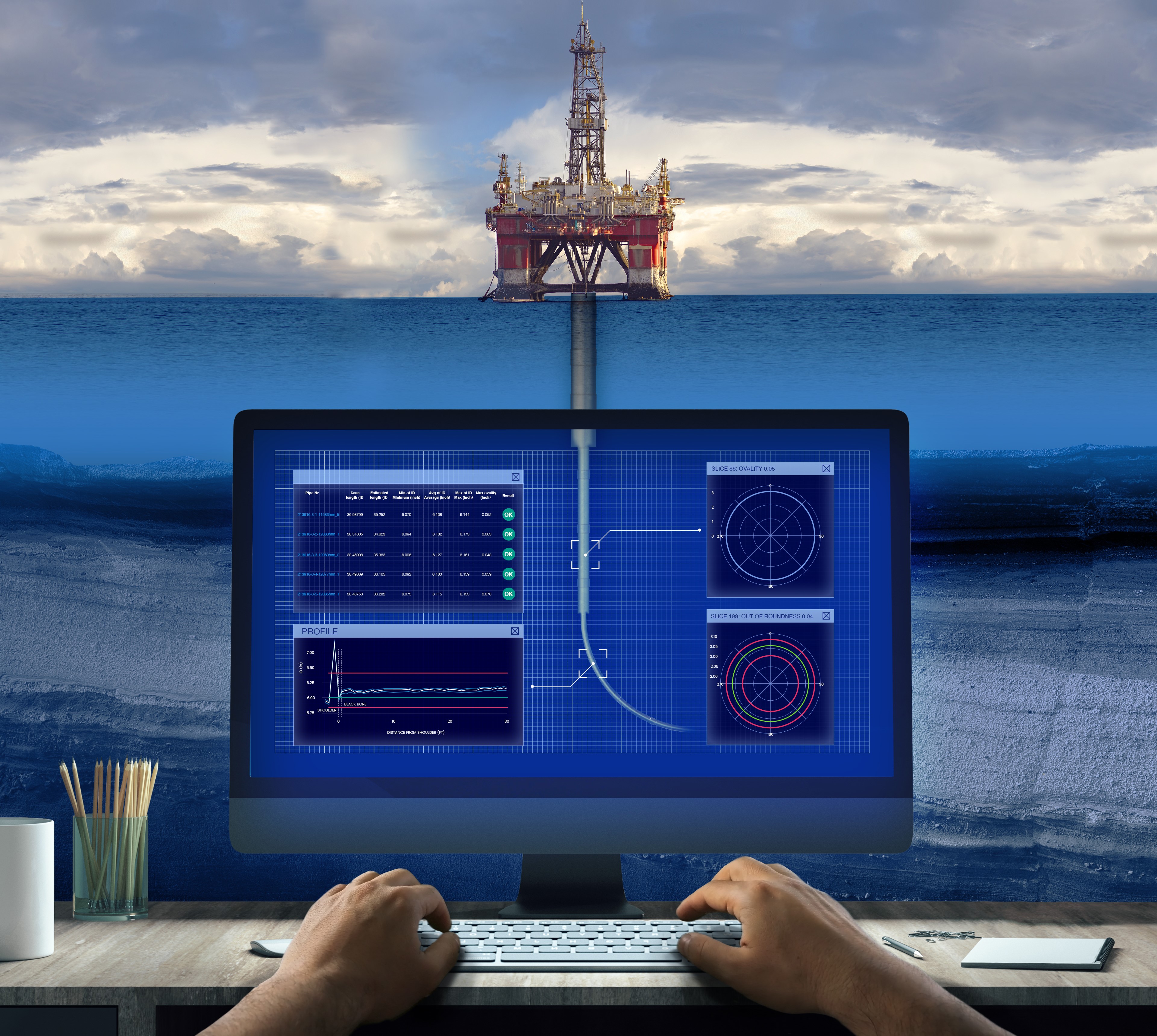

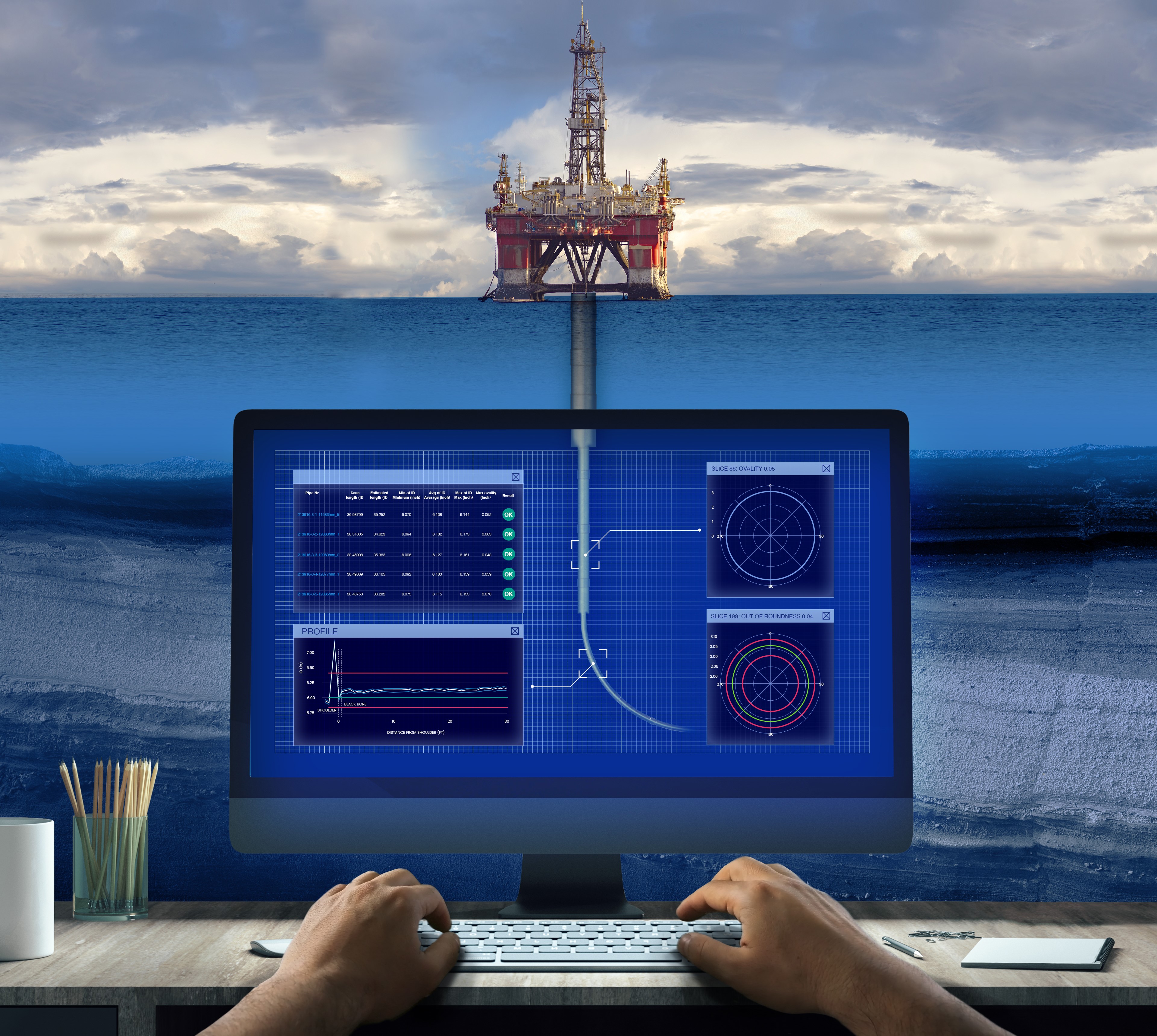

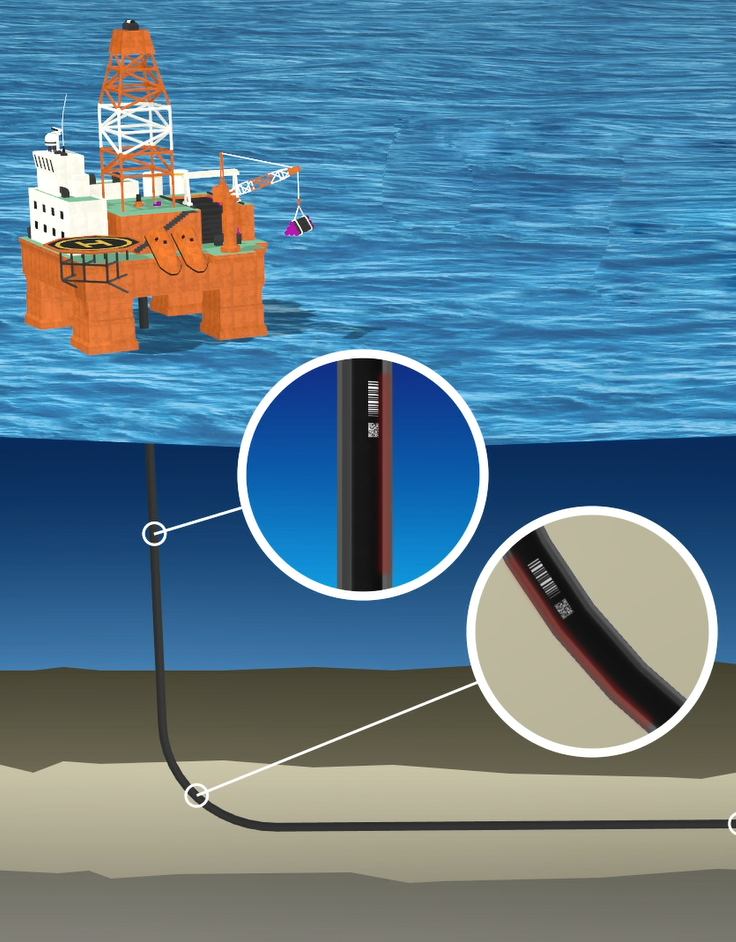

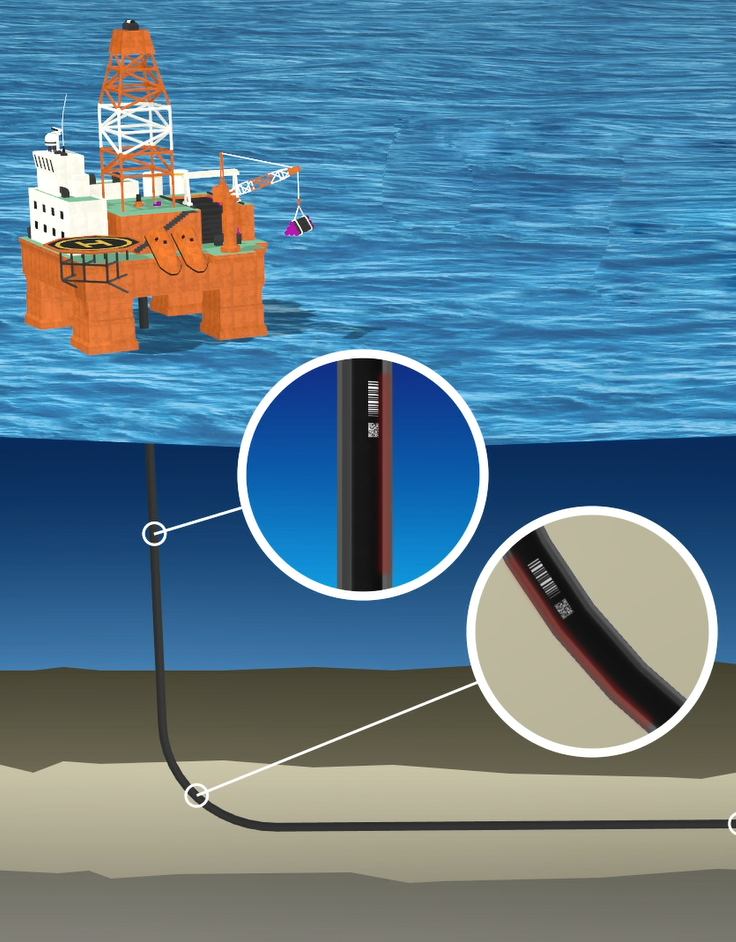

This starts either at the customer’s yard or rig, Vallourec’s own yard, where a VAM® Field Service technician performs measurements on all pipes to be run. Using an automized device called In-pipe Rover, it takes around three minutes to conduct a 360° mapping of the full length of each pipe. The rovers use either laser technology or ultrasound to map each pipe and relay the measurements wirelessly to the technician’s computer for data readout.

“Our technicians can perform the service on our products, or on those of other suppliers,” Binh says. “We can also provide service directly on the rig if needed.”

Once the data for all tubing and casing has been obtained, the technician proposes string optimization before sending and running the pipes. Joints are selected for their optimal purpose and organized for running order. These Prime Mapping optimizations enable time and cost savings without compromising on safety and accuracy.

What kind of data, and why is it important?

There are three main kinds of data collected by Prime Mapping:

Pipe actual bore volume

Traditionally before drilling, an operator does a pre-run tally list for each tube, which includes information around the tube’s origin, specifications, and dimensions. However, in most cases these measurements are imprecise, leading to miscalculations in cement operations which means operators can encounter bad cement displacement and left-in-hole cement.

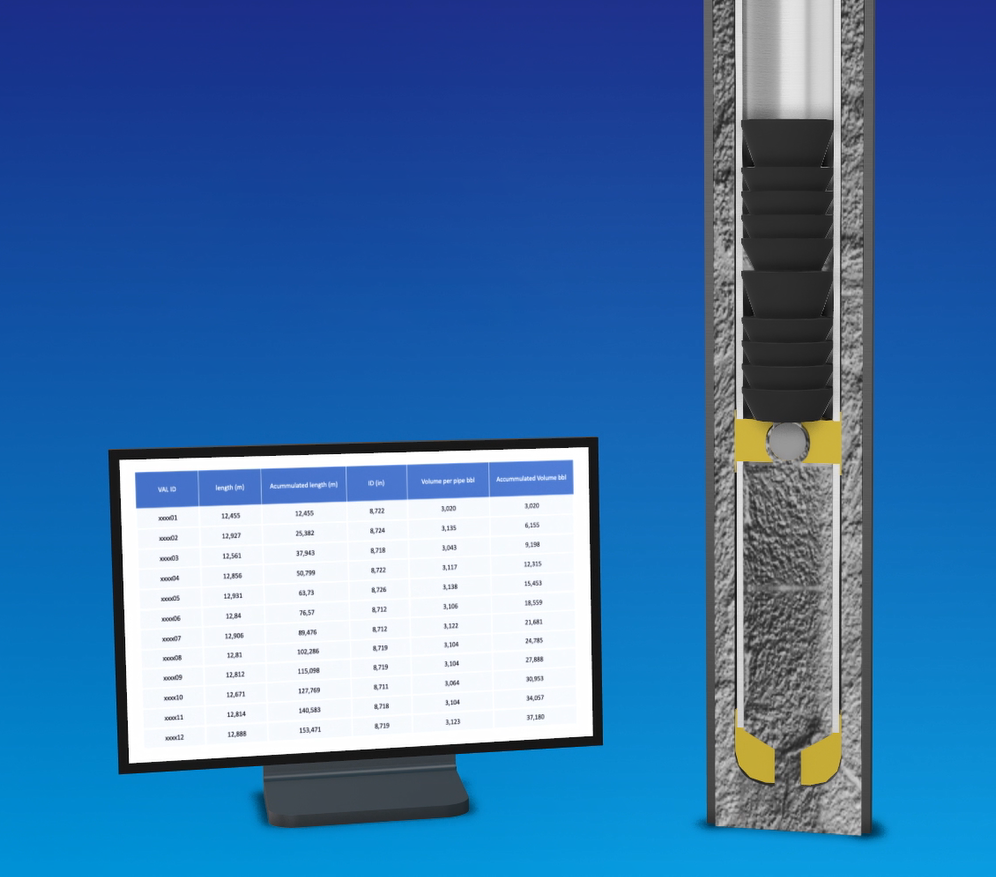

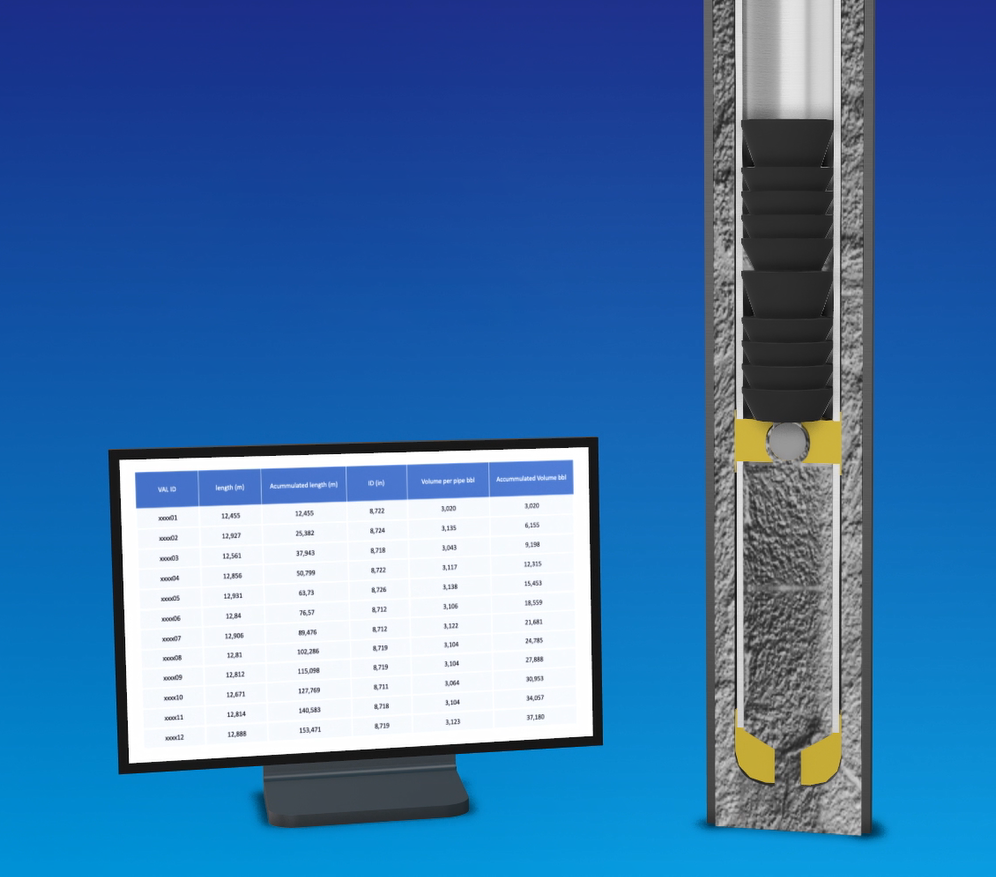

With Prime Mapping, operators receive the pipe’s precise volume by measuring the exact length and ID. Instead of relying on nominal data, operators know exactly every joint’s bore volume before running. Prime Mapping provides cement and mud engineers with the exact capacity of the string and how much displacement mud volume they need to pump.

“That’s the added value of Prime Mapping,” Binh says. “Accuracy is our promise to our customers.”

Best packer-fit pipe selection

Packer pipe equipment runs inside the well to isolate different zones that will either require different pressures or contain different liquids that cannot be mixed. Running a packer in a hole can thus be quite challenging. Operators need the packer to run smoothly, setting and sealing with no gaps or leakage.

With a 360° full-length pipe ID profile, VAM® Field Service technicians can help operators to identify which pipes are within the packer’s thresholds with the lowest out-of-roundness. These are then selected as packer pipes, helping operators avoid the issue of leakage and pull-out-of-hole (POOH).

“With Prime Mapping, we’ve eliminated the problem of leakage that can occur when a packer is improperly set within a pipe,” Binh says. “Verifying the pipes’ ID min/max/avg and out-of-roundness ensures that the pipe is the right fit for the packer.”

Thickest pipes for casing wear mitigation

As drilling progresses down a well, the well is almost never vertical. The drill string may lean to one side to compensate for deviation, creating friction and thus casing wear on the affected side. In some critical depths, the operator needs thicker pipes that allow for a larger casing wear margin for the drilling to be safe and efficient. Vallourec’s Prime Mapping technology can measure hundreds of joints and then select a key few that are thickest and have the best eccentricity for these important sections of the operation.

Maximizing customer benefits

“All of these factors can mean less non-productive time (NPT) onsite,” Binh says. “NPT is always a problem in well operations. With accurate data provided by Prime Mapping, there are fewer chances for errors that can cause delays. And fewer delays translate to cost savings, and a reduction in CO2 emissions associated with the operation of onsite machinery.”

Around the world, Vallourec is putting its Prime Mapping to good use in the service of its customers. International oil companies (IOC) from Brazil to the North Sea are seeing the value of the service.

“The North Sea is always a challenging area,” Binh says. “But we were able to help an IOC there who was struggling in setting its packer on top of the 7” liner due to tight downhole space. With Prime Mapping, we helped them select the best-fit packer joints by using the 10” casings’ full-length 360° ID map. It’s proven to be a really pivotal solution. Our innovation is made possible thanks to our strong relationships with our customers, who trust us to come up with solutions that work for them.”

Prime Mapping has proven to be one of these trusted solutions because it is easy to use and accessible for customers. Together with Smartengo Running Expert, Prime Mapping prepares the most thorough run-in-hole tally and accompanies customers in building their wells’ digital twin.