Intelligent Pipe Solution: Monitoring your well from the inside

On June 8, 2021, Vallourec and World Oil held a live webcast showcasing Vallourec’s Intelligent Pipe Solutions. François-Xavier Bulard, Vallourec’s Intelligent Pipe Project Manager, and Emmanuel Tavernier, R&D Manager for OpenField Technology, presented a solution that enables users to monitor wells from the inside.

The webcast was a major success with 304 participants, 156 live attendees, and more than 33 questions asked throughout the presentation with 17 replies provided live.

Targeting well integrity

Well integrity to prevent catastrophic damage has always been a key focus of the oil and gas industry, and operators continuously work to reinforce it. However, well integrity data available throughout the life of the well remains limited.

Intelligent Pipe Solutions offer operators a new tool to understand and monitor their wells more closely. The solution integrates an innovative pressure and temperature sensor based on microelectromechanical systems (MEMS) placed directly on pipes, which allows operators to monitor previously inaccessible areas of the well in real time. This approach is new and, leveraging the latest Internet of Things (IoT) technologies, ushers in a new era for optimized data-based oil and gas well monitoring.

The benefits of joint expertise

Intelligent Pipe Solutions are based on the know-how of two recognized companies: Vallourec and OpenField Technology.

“The product draws on each company’s core field of expertise: Vallourec’s knowledge of connections, well integrity and material corrosion, and OpenField’s work with miniaturized sensing technology for down-hole applications. For Vallourec, it is part of a wider innovation strategy to support customers now and into the future,” said François-Xavier Bulard, Vallourec’s Intelligent Pipe Project Manager.

The primary advantage of Intelligent Pipe Solutions is in making accurate well data available to operators in real time.

“The objective of Intelligent Pipe is to allow access to inaccessible areas, for example in sub-sea wells,” explained François-Xavier. “Deploying this system enables operators to perform APB monitoring to optimize production. It both reduces the risk of start-up failure and enables companies to react faster in the event of abnormal well behavior. The system also provides information on its environment, including formation behavior – for example, monitoring the movements of a salt dome. In addition, it lets users learn about their actual well loads in order to optimize well design.”

Long-term, the system can help with decommissioning by providing data regarding the integrity of the annulus and the quality of the permanent barrier. Ultimately, Intelligent Pipe is a solution for the entire well lifecycle.

The technology behind the advantages

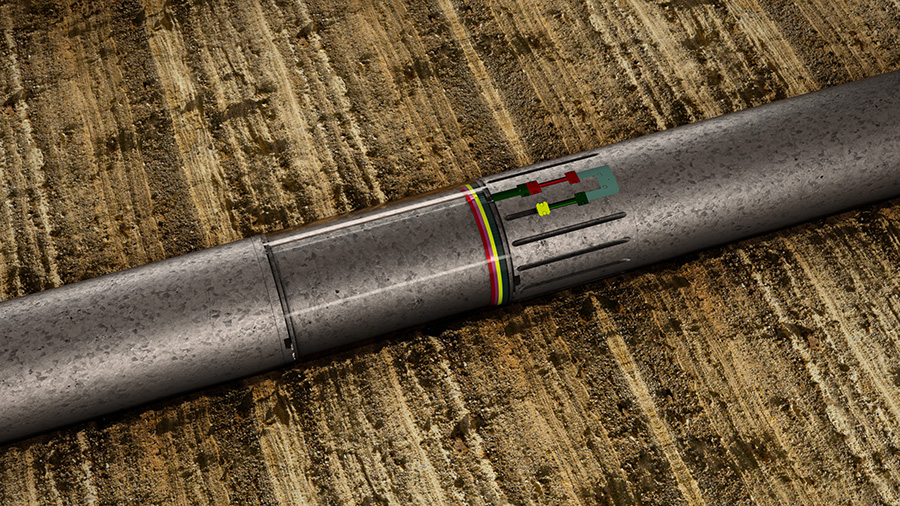

Simple and easy to use, Intelligent Pipe offers operators eyes inside their well. “The system is made of a casing monitoring mandrel and a tubing transmission mandrel which are inserted into the well,” detailed François-Xavier. “Power is supplied and data retrieved via the same electrical cable, and horizontal transmission is performed by a magnetic field and is possible thanks to the use of non-magnetic pipe.”

The Intelligent Pipe Solution’s multi-annulus monitoring technology is made possible by OpenField’s microelectromechanical systems.

“At only a half-inch in diameter, our compact chip is the slimmest sensor on the market,” said OpenField’s R&D Manager, Emmanuel Tavernier. “It is integrated into the pipe with its own microelectronics and offers extremely high sensitivity during transient mode. As well as being almost compatible with all casing combinations and well designs, the chip also consumes very little power.”

The system is designed to cover the well’s entire lifetime. “The Intelligent Pipe Solution uses Inconel wetted parts and connections that deploy high-pressure, high-temperature single-pin feedthroughs with boots,” explained Emmanuel. “The state-of-the-art electronics have been qualified for continuous high-temperature operations, and the sensors it uses have an extensive track-record of down-hole application success. The target is an operational lifetime of 30 years at 125°C.”

An additional advantage of this system is its qualification as a VAM® connection. “The system has a single design for monitoring mandrel compatible with all casing sizes and for transmission mandrel compatible with all tubing sizes,” specified François-Xavier. “It has undergone the same analyses as other VAM® connections including FEA evaluation, and the mandrel was successfully tested against ISO 13679 and API 5C5 requirements.”

What’s next?

Over the course of 2021, the Intelligent Pipe Solution will undergo field trials and long-term tests on the monitoring and transmission system. Work is also in progress on a plug-and-play version of the solution compatible with third-party telemetry. A qualified, permanent solution should be available by the end of the year.

Our aim is to offer a simple, modular and customer-friendly solution that is the most competitive on the market due to its slim design. Our priorities are, as ever, our customers’ ultimate goals of optimizing production and safeguarding the well lifecycle.

Vallourec & OpenField Technology: an Open Innovation success story

In 2017, Vallourec launched its first Open Innovation challenge. Dedicated to all things”smart tubes”, this challenge saw more than 40 start-ups and companies from around the world submit ideas. Preselected among these companies, OpenField Technology was invited to pitch its proposal, “OpenField measurements in pipes“, in front of an international judging panel and was selected as the winner of the challenge.

Know more about Vallourec Open Innovation challenge

Keeping the technical dialog open with our customers…

At Vallourec, we are committed to staying in close contact with our clients and prospects, supporting them with our products and services. This webinar is part of a series designed to explore their technical challenges and explain how we can help overcome them.

If you missed out…

You can play recordings of our past webinars whenever you want. Simply click on one of the following links to access the topics that interest you: