Making hydrogen storage the foundation of tomorrow’s energy mix

Hydrogen will surely play a significant role in contributing to global emission reduction targets. Over 50 countries already have policies promoting hydrogen development. The European Union’s REPowerEU initiative aims to produce 10 million metric tons of green hydrogen by 2030 (and to import another 10 million metric tons from overseas). In the United States, the Inflation Reduction Act is funding half a dozen new hydrogen hubs and is targeting a roughly 40% reduction in carbon emissions by 2030. The message to energy companies, equipment manufacturers and off-takers is clear: hydrogen is coming.

Governments have compelling reasons to encourage hydrogen development. For heavy industries such as petrochemicals and steelmaking, low-carbon hydrogen can be a direct substitute for fossil-based feedstock (starting with pre-existing “gray hydrogen” usage).

For the transportation sector, hydrogen can be used to make e-fuels, which can sustainably power ships and airplanes, or directly in the form of dihydrogen. Hydrogen is also valuable as an energy carrier and an intermittent energy source: unlike the electrical energy from wind or solar, hydrogen can be produced, stored and delivered at all times.

However, scaling up energy and manufacturing systems to run on hydrogen won’t happen overnight. Countries will first need to build a reliable, high-quality hydrogen supply chain, backed by political support, long-term investment and regulations. This is particularly true for hydrogen storage, a step in the hydrogen value chain that is crucial to balancing hydrogen supply and demand.

The colors of hydrogen

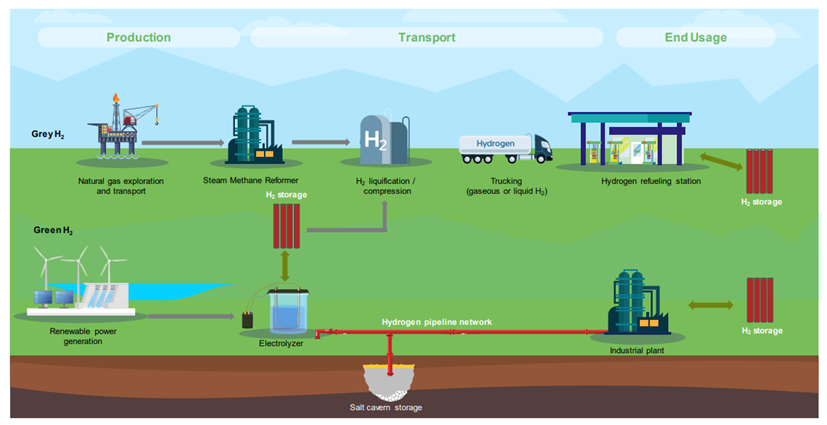

Based on its production method, hydrogen receives different designations. Some of the most common are:

- Gray hydrogen, made from natural gas or methane, through steam methane reformation without capturing greenhouse gas emissions.

- Blue hydrogen, also made from natural gas or methane, also through steam methane reformation, but the emissions are then captured using carbon capture technology.

- Green hydrogen, made from renewable energy, such as wind or solar, which powers the process of water electrolysis, creating almost no emissions.

Ultimately, the end goal is to reduce CO2 emissions along the value chain. The carbon intensity of hydrogen production and use should be the most relevant criterion, and our ambition lies with the development of low-carbon hydrogen.

The hydrogen value chain

Hydrogen production starts with natural gas extraction for gray and blue hydrogen, and wind or solar energy generation for green hydrogen. Following steam methane reformation or electrolysis, the resulting hydrogen can be transported for direct use at industrial plants and hydrogen refueling stations. Hydrogen can also be stored, either in containers or in natural storage areas, such as underground salt caverns.

Both storage options will be crucial to expanding hydrogen’s availability. Underground salt caverns can hold thousands of metric tons of hydrogen, making them ideal for large-scale projects, interconnected with a pipeline grid and supporting, for instance, seasonal balancing. When, and where, pipeline and underground storage infrastructure is not available, security of supply and production optimization will rely on distributed storage. This must be located near production sites or end-use facilities, and would have to handle up to a few dozen metric tons of hydrogen.

Overcoming hydrogen’s supply chain challenges

When it comes to the hydrogen supply chain, companies and governments tend to focus on production and use, viewing storage and transportation as secondary. However, there is no way to build a safe, efficient, cost-optimized hydrogen supply chain without developing these two steps. This makes the first challenge of the hydrogen value chain one of simultaneity – building out all stages at once. Hydrogen storage can create value along the various stages of the value chain:

- Hydrogen production by electrolysis faces issues of variability of electricity availability and price, as hydrogen production often depends on intermittent energy sources. Producers can use hydrogen storage to optimize the electricity mix they use, and improve the competitiveness of hydrogen production. Otherwise, they can simply use storage to offer stable output, regardless of the power source’s intermittency.

- Midstream steps in the hydrogen chain involve transport and distribution. In many circumstances, this can involve a storage need. This might be the case, for instance, at hydrogen refueling stations (HRS), where a buffer of high-pressure hydrogen is needed to guarantee the refueling of several vehicles consecutively at any time. And the same applies to fill trailers to ship hydrogen from producer to offtakers.

- Downstream, the challenges for hydrogen revolve around supply consistency. End users in industries such as shipping and steelmaking require a high degree of continuity and the assurance that hydrogen will be continuously available. A buffer storage will ensure this consistency and can accompany the ramp-up and ramp-down phases of the production regime, in case of unexpected events.

Of course, safety is a non-negotiable prerequisite whenever storage is involved, as hydrogen is explosive, corrosive and flammable.

Safe and proven tubes for hydrogen infrastructure

While hydrogen provides a strong path for accelerating the energy transition and decarbonizing carbon-heavy industries, it needs to be developed the right way. Safety is of the utmost priority. For Vallourec, this means tackling challenges like steel embrittlement and leakage as early as the R&D phase.

Steel embrittlement is a phenomenon where hydrogen degrades steel, creating cracks in materials. To combat this, Vallourec’s experts leverage their expertise in mastering corrosion challenges to select and validate the best materials for use in hydrogen applications. This has been supported by numerous tests, which confirm the superior performance of Vallourec’s steel ranges for hydrogen applications.

For leak control, Vallourec has developed demanding protocols for testing connection tightness for vertical hydrogen storage units. Its tests incorporate feedback from customers, aiming to replicate the environments where solutions will actually be used, such as salt caverns. Vallourec has developed a specific R&D plan to assess material performance. Specifically, VAM® 21 premium connections have demonstrated excellent tightness, with no significant or measurable hydrogen leakage.

Vallourec is well equipped to support customers’ hydrogen infrastructure projects, with pipes and connections for underground salt cavern storage, ground storage in high-pressure cylinders, and H2 pipeline transport. Thoroughly R&D-tested at our Aulnoye (France) site, our pipes and connections also boast a strong track record in the field. Vallourec products are already used by Storengy, Gasunie, Uniper and EWE in several hydrogen projects across Europe.

Vertical storage: an innovative solution to revolutionize hydrogen storage

Safety must underpin the entire value chain, as well as every stage of vertical storage unit development. As a consequence, the permitting phase of a hydrogen project can pose difficulties. All proposed facilities, for example, must be mutually compatible. This means they must be compatible with each other, as well as with their neighboring environments, even when faced with various constraints (such as a lack of available space).

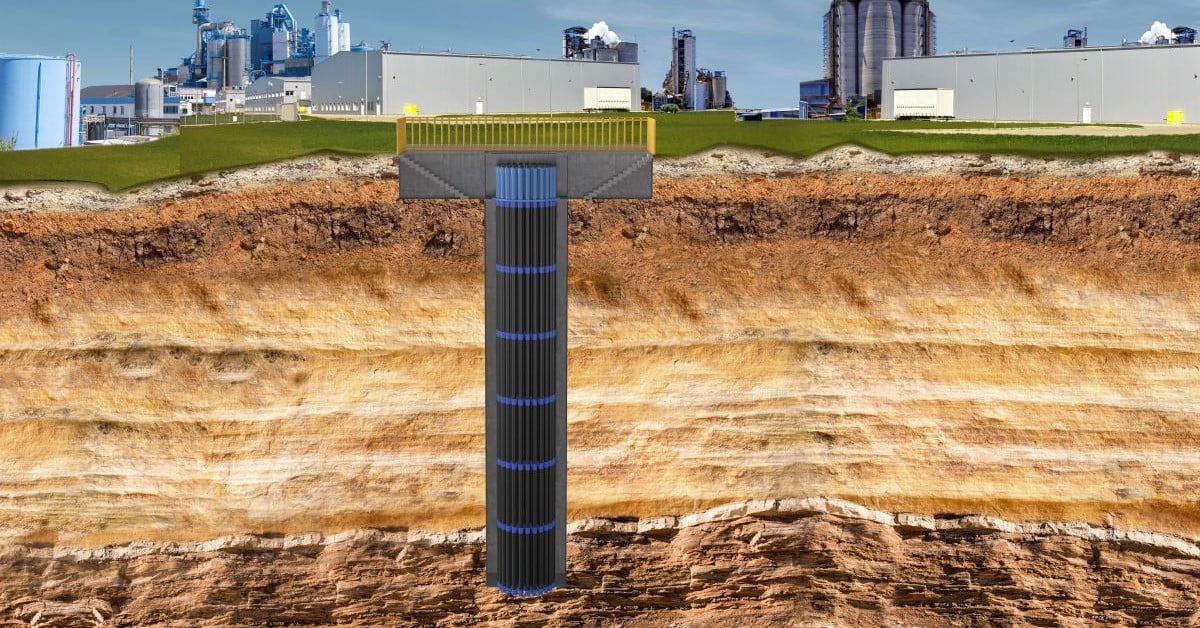

To address these challenges, Vallourec is bringing to the market an innovative solution, where hydrogen is stored in vertical units. This offers a superior safety profile, along with minimal surface footprint requirement, and it supports faster permitting and integration into industrial projects.

This underground solution relies on hydrogen-tight tubes, using hydrogen-proven Vallourec pipes and connections, which are installed in an excavated shaft. (The construction of the shaft is a conventional and well-mastered civil works type of project similar to foundation works, ventilation shaft installations, etc.)

The main advantages of the solution for Vallourec’s customers are:

- High safety profile, thanks to proven components (materials and connections), vertical subsurface architecture (minimizing hazards), and a stringent qualification program to further enhance the solution.

- Easier permitting, supported by minimal surface footprint and safety performance, which enables hazard mitigation, set-back distances and potential domino effects on other facilities

- Cost-effectiveness, thanks to the optimized size of storage vessels, and support from Vallourec’s full lifecycle services

- Modularity and flexibility: unit size can be determined by the end user, ensuring hydrogen availability at the scale required

- Low CO2 footprint, benefitting from Vallourec’s best-in-class credentials

Drawing on the Group’s expertise and experience in developing safe, reliable solutions for hydrogen, Vallourec currently has four patents pending for vertical hydrogen storage units. The technology has already attained solid maturity because it relies on existing components. Nevertheless, Vallourec is undergoing a comprehensive technology qualification program, with support and challenge from third-party expert DNV, to provide solid evidence of the safety and reliability of the system. As part of this program, a Proof of Concept is under construction in Vallourec’s premises in Northern France, to support the test plan and build experience with the solution.

While we are pursuing development in geographical areas with high added value, such as Europe and the United States, our ambition for hydrogen storage is global. Our goal is to develop and sell complete solutions for hydrogen storage, including a long-term service offering.

Historic expertise for a new market

Vallourec has a long history of excellence in developing seamless steel tubes for a wide range of industrial applications and the oil & gas sector. For decades, Vallourec has supplied solutions for underground wells and caverns, thus developing its in-depth knowledge of safety issues and how to work in hostile environments. The Group leverages extensive expertise in materials science, including metallurgy, corrosion and mechanical fittings, bringing excellence and a proven track record to every project.

As the energy transition accelerates, Vallourec is committing its expertise to more sustainable solutions, including hydrogen, carbon capture and storage, and geothermal energy. To fortify this commitment, the Group unveiled Vallourec® New Energies, a new strategic outlook and roadmap to best support collaboration across all renewable energy projects.

The Group took its first steps in the hydrogen sector in 2019, and has been at the forefront of hydrogen development ever since. Vallourec sees the hydrogen market as a dynamic driver of technological advancement and renewed industrial partnerships.

At Vallourec, we plan to continue building technologies for hydrogen storage, helping bring the hydrogen supply chain to life. By applying our innovative research and development techniques, we have been able to develop safe, proven, unobtrusive solutions. We are creating hydrogen storage opportunities where none existed, overcoming challenges that impact every hydrogen project.

Innovating today for hydrogen’s future

Hydrogen will be a crucial part of the future energy mix, with many countries developing gray, blue and green hydrogen projects. According to the IEA, the low-emissions hydrogen projects announced worldwide are already poised to meet 55% of what’s needed for a net-zero scenario in 2030.

This is a strong start, but accessing the full benefits of hydrogen production means building innovative storage solutions. Vertical storage units have a role to play in both large- and small-scale applications, providing a versatile solution for hydrogen producers and end users. As a market leader in tubular solutions that are instrumental for hydrogen transport and storage infrastructure, Vallourec is supporting clients with cutting-edge, reliable technology like its innovative vertical storage units, making large-scale hydrogen storage possible!