Pushing the limits of VAM® CO2 injection testing protocol

Industries are more than ever interested in carbon capture & storage (CCS) to lower CO2 emissions, maintain global warming under 2°C and accelerate the energy transition. Vallourec joined the momentum in 2021 by developing a testing protocol validating its VAM® connections for CO2 injection. Today, with incoming orders increasing in number, Vallourec has pushed the limits of its testing protocol, assuring product integrity in the most critical of CO2 injection applications.

When research started on carbon dioxide injection, some operators believed that well conditions would be similar to those found in OCTG applications. After further research and testing, we now know that CCS well lifecycles are much more critical than OCTG wells’, therefore requiring specific and more rigorous testing to validate OCTG products for CO2 injection and storage.

Increasing the pressure and injection rate

When an operator approached Vallourec with specific CO2 injection well loads and requested to validate VAM® connections to a higher number of cycles, Vallourec took up the challenge. But to validate its connections to such critical performances, Vallourec had to expand its existing testing protocol developed in 2021.

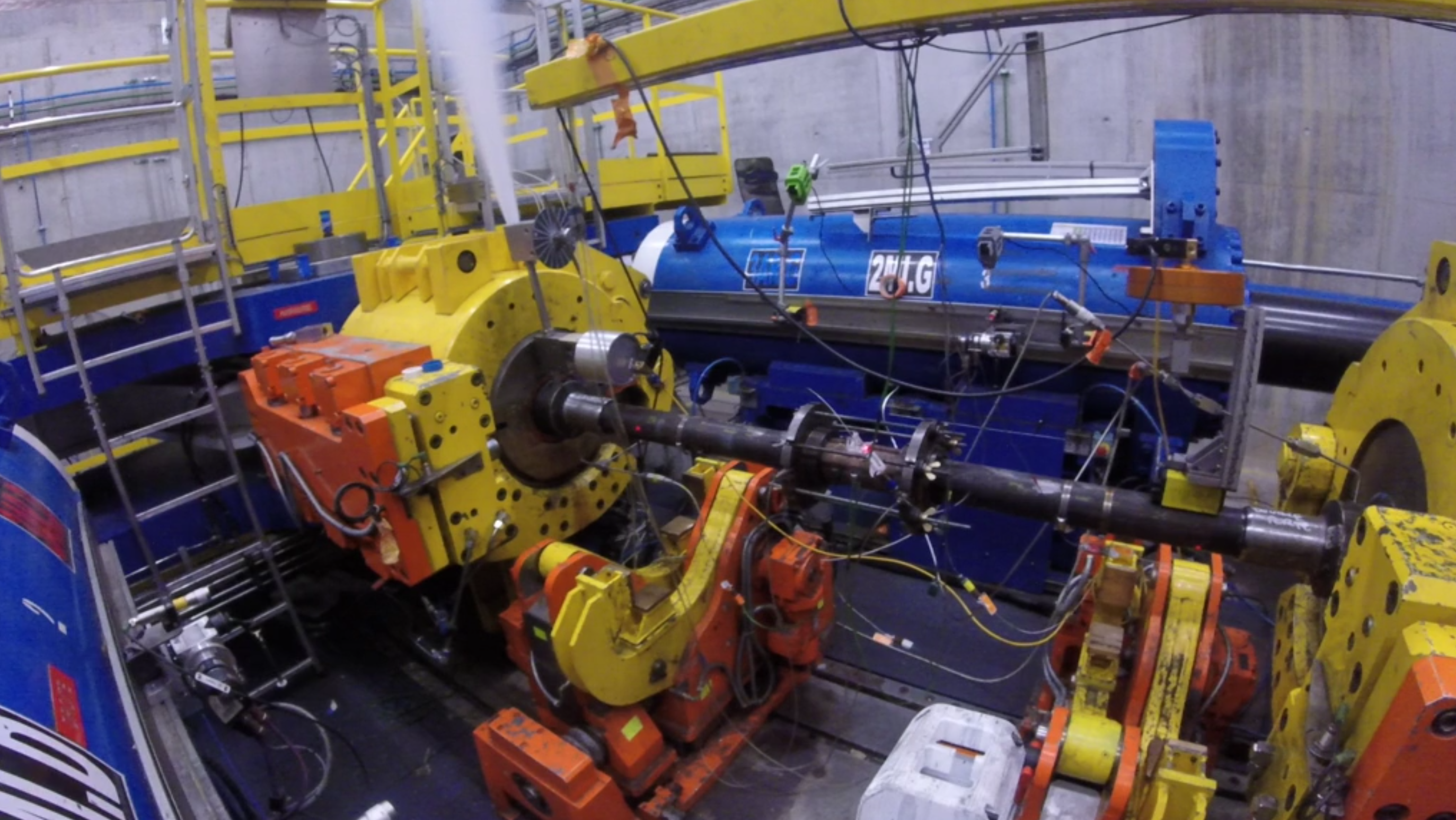

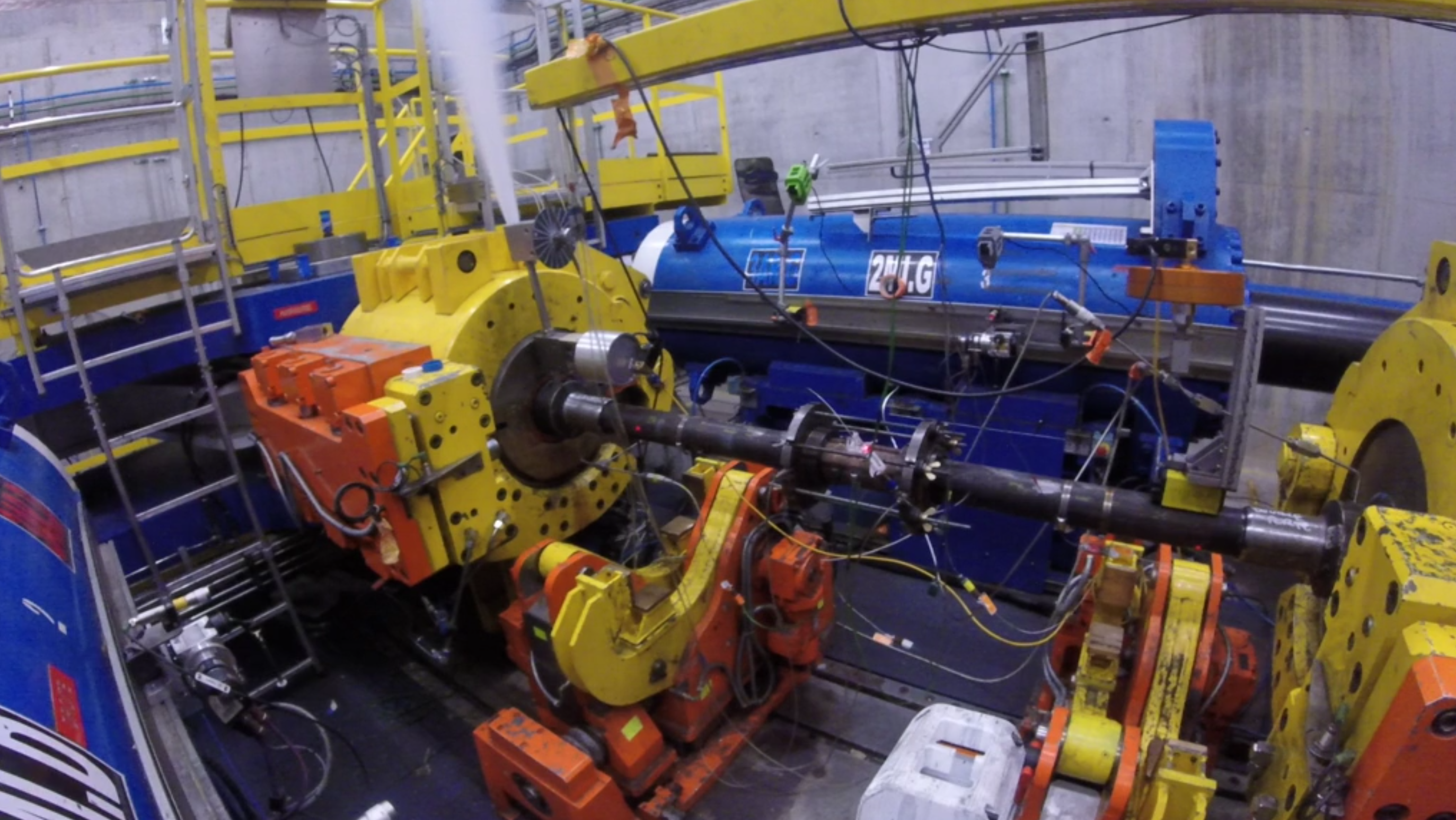

“Phase 1 consists of a traditional operational assessment found in Oil & Gas protocols”, explains Pierre Mauger, Vallourec R&D Engineer. “Phase 2a is where things start getting more critical. We test the connection in 500 temperature cycles between 40°C and -20°C at constant 100% tension CEE (Connection Evaluated Envelop). At 473 bar external pressure coupled with tension, we expose the connection up to its laminating limit”.

Next up is phase 2b where the temperature is kept stable at -30°C at 50% tension CEE and the internal pressure is cycled 500 times between 255 +/- 25 bar. These two cycling phases simulate real-life CO2 injection phases of multiple injections over several years of well use. Phase 3 will then evaluate the connection’s resistance to a blow-out scenario by lowering the temperature to -80°C in less than five minutes.

Phase 4 is even more critical still, maintaining an 80°C delta temperature between pin and box at 100% pressure to evaluate the connection’s sealability after a rapid depressurization inducing the Joule-Thomson effect. “This is a very complex test to carry out”, says Pierre Martin, Vallourec R&D Manager. “In order to maintain the pin at a very cold temperature while threaded to a box intentionally kept at a very high temperature, we had to develop new testing measures and tools capable of handling the temperature difference”.

Finally, a last phase of tests identical to the first provides operational confirmation of the connection’s sealability after the well returns to its normal state.

This new testing protocol includes 20% more tension and compression than our 2021’s protocol, reaching 80% connection yield strength and 90% internal and external maximum yield pressure while also assessing several more injection cycles (from 75 to 500). The first connection that was tested according to such a rigorous CO2 injection protocol was 3 ½” VAM® 21 CLEANWELL® with additional connections and dimensions to come later in the year.

“Once we have physically tested several connection ODs, we will be able to finalize our FEA protocol that will quickly evaluate additional sizes through simulation to compare their key performance indicators against the physically-validated sizes”, explains Pierre Martin. “This means that when a customer approaches us with a request to evaluate a specific OD for CCS, the process will be much quicker than the current six to seven weeks of physical tests”.

Ready for all scenarios

With incoming orders increasing in number, Vallourec’s newly updated CO2 injection protocol provides customers with real-life results and the reassurance they need to confidently run their CO2 injection wells. In addition, the validation of dope-free solution CLEANWELL® provides customers with an alternative to standard compounds, improving running performances and reducing environmental risk for a complete low-carbon offer. Further tests on additional ODs and grades will take place soon, providing operators with a portfolio of validated solutions for a wide range of CO2 injection applications.

We are currently seeing a strong acceleration in the market, with several dozens of CCS projects in an advanced engineering stage. We had anticipated this momentum, collaborating with our customers and including extreme conditions in our physical testing protocols. Today, we are ready to provide all CCS operators with connections tested under the most robust protocols for CCS projects currently available in the industry.