Real data to enhance your rig preparation

On December 9, 2020, Vallourec hosted a live webcast on our Intelligent Drift Solution, a direct response to a real client need. OCTG Services Project Manager, Binh Nguyen, and Lucas Kling, an R&D engineer specializing in non-destructive evaluation, explained the benefits of the new solution and shared in-depth insights into associated applications. The webcast attracted more than 160 participants from the oil and gas industry.

Vallourec’s Intelligent Drift Solution is a response to feedback received from clients regarding their need for real and accurate casing data for critical operations.

In the current drilling and completion context, nominal casing data is simply not enough. Operators need actual casing dimensions for critical operations, exact cement displacement volumes, and an optimized string for casing wear mitigation. One client cited, for example, the need for actual interior and outside diameters (ID and OD), since success relies entirely on accurate volumes.

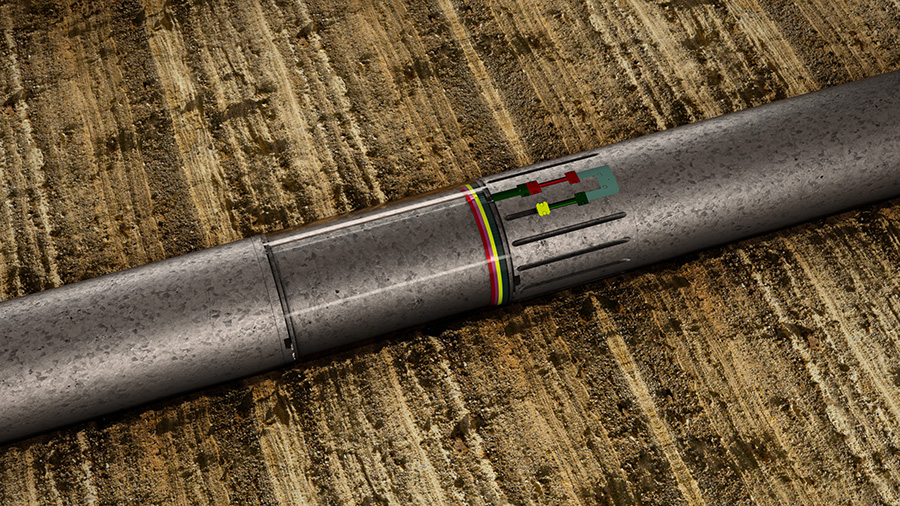

“We have developed a device to measure pipe length and ID while drifting,” explained Lucas Kling. Thanks to a self-propelled drift and ID measurement system, Vallourec’s patented solution makes it possible to acquire an automated tally list from rig preparation service without any additional steps.

Multiple benefits and applications

There are three main benefits of using the Intelligent Drift Solution.

- Enhanced reliability. Accurate and real data can help estimate volumes, increasing operation reliability. Reducing inspection steps improves safety and avoids human error.

- Cost and time savings. Accessing actual data reduces rig time and costs. Plus, it reduces pipe transportation costs, shrinking carbon emissions.

- Better operational performance. The solution is customizable to the needs of clients, offering a perfect fit and maximum boost.

“Another application of the solution is for access to actual bore volume per pipe to enhance plug bump reliability and ensure horizontal section clearance for perforation, thus optimizing cement operations. The last is ID mapping for string condition documentation to support inspection services. The solution allows users to document casing ID mapping of initial pipe conditions to compare at a later time, evaluate wall loss on workover risers and tubing, and inspect untraceable pipes,” says Binh Nguyen.

Tried and tested for peak performance

“Initial validation of the Intelligent Drift Solution was performed in our testing facilities in Brazil in February 2020,” recalls Kling. “Based on feedback received during this early phase, we made improvements and performed further validation tests in France to ensure its capabilities – both at our R&D sites and within a client context. The solution now achieves length accuracy of around 6 mm, ID accuracy of 0.1 mm, speeds of 1-3 minutes per pipe, and ID mapping of about 900 slices per pipe”.

The equipment was piloted with a client in the North Sea in October 2020. As a result, the Intelligent Drift Solution is available in all regions as of 2021.

Keeping the technical dialog open with our customers…

At Vallourec, we are committed to staying in close contact with our clients and prospects, supporting them with our products and services. This webinar is part of a series designed to explore their technical challenges and explain how we can help overcome them.

If you missed out…

You can play recordings of our past webinars whenever you want. Simply click on one of the following links to access the topics that interest you: