THERMOCASE® VIT for Geothermal Applications

THERMOCASE® Vacuum Insulated Tubing (VIT): a cost-effective solution for Geothermal Applications

28/07/2020 – Renewable Energies

On July 22nd, Gabriel Roussie, THERMOCASE® Product Line Manager, shared the specificities and benefits of Vallourec’s THERMOCASE® VIT solution in a webcast presentation with World Oil. More than 230 participants learned about how this technology is an ideal candidate for geothermal applications, thanks to best-in-class insulation performance and high-service temperature and got an insight into the successful closed-loop project with GreenFire Energy.

THERMOCASE® VIT for geothermal applications

Geothermal wells can be used to extract energy from beneath the earth’s surface in the form of water or steam to generate electricity or feed district heating. However, conventional well systems can be costly to drill and are not suited to all projects.

California-based GreenFire Energy set out to resolve these issues using Vallourec’s THERMOCASE® VIT.

The challenges posed by open-loop systems

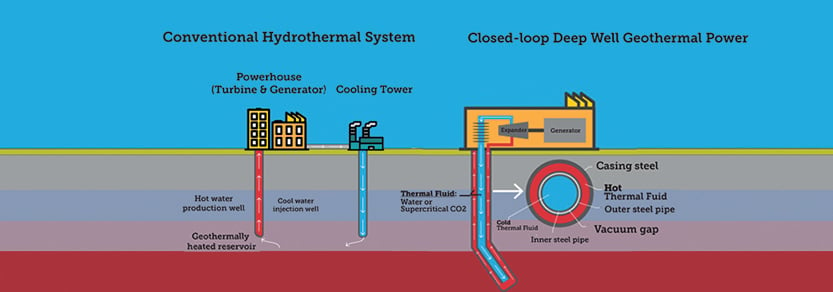

The conventional method for commercial use is an open-loop system which utilizes two wells: an injection well and a production well. Water is pumped down the injection well and flows out through fractures in the brittle zone. Geothermal energy then heats the water, which flows up through the production well.

This system works well but has several disadvantages. The first is that the two wells sometimes fail to communicate due to a lack of subsurface permeability. In these cases, they produce no hot water or steam. The second is that water is highly corrosive and may not be the ideal heat carrier for certain projects. The third is that the initial cost of drilling two wells is high.

Open-loop systems can work well, then, in areas with adequate water and permeability. But these areas are comparatively rare. New solutions are needed to access this valuable source of energy in the vast geothermal regions where conventional technology is infeasible.

Enter GreenLoop™, an efficient technology using Vallourec tubing

Just over five years ago, GreenFire Energy Inc. – a California based Geothermal Energy company – set out to develop a new technology to expand the scope and reduce the cost of geothermal power generation. This new technology, branded GreenLoop™ is able to use supercritical carbon dioxide (sCO2) or water in a closed-loop system..

GreenFire uses a “tube-in tube” system, with Vallourec vacuum-insulated tubing (VIT) as the key component. This system can be used for many applications, such as retrofitting unproductive wells.

As such, GreenLoop™ eliminates the need for two wells. For example, cold sCO2 fluid is injected inside the center of the tubing. Once the fluid reaches the hot underground formation, it heats up. The heated fluid then travels upward through the outer annulus of the tubing and is produced to the surface, where it is used to power a turbine. After cooling to maximize efficiency, it is re-injected into the VIT, to complete the closed loop.

Supercritical CO2 allows for much better cycle efficiency compared with water. This is thanks to unique thermodynamic properties that create a “thermosiphon” where the cold dense column of sCO2 pushes the less dense column of heated pressurized sCO2 through the system. The thermosiphon eliminates the need for pumping fluid through the system, thereby saving a significant parasitic loss of power.

The design of the system with hot and cold fluids in close proximity does, however, pose a specific challenge: thermal insulation. To achieve maximum energy recovery at the surface, it is essential to provide excellent thermal insulation between the hot fluid on the ID of the tubing and the cold fluid on the OD.

THERMOCASE® VIT is an ideal candidate for such application, with best in class insulation performance and high service temperature. Due to the nature of the pilot, some specific performance required adjustments of design parameters to allow safe performance of the VIT in the field during the test.

Successful industrialization and testing of a promising new technology

Vallourec Tube-Alloy, which produces and repairs accessories used inside oil and gas wells, completed industrialization of the custom VIT solution on-time and successfully delivered the first reverse preload VIT to GreenFire Energy at the beginning of 2019. We then supported the successful running using Smartengo Running Expert under the supervision of VAM® Field Service.

As a result, GreenFire Energy successfully completed construction and began testing the power system in the early part of 2019. The pilot well generated 1MW of power using only water, a level of performance in line with expectations.