Vallourec: Deep expertise in sour service

On November 5, 2020, Vallourec held a live webcast introducing the latest developments in our comprehensive tubular offer in high-strength sour service grades. Presenting for Vallourec was Jonathas Oliveira, Vallourec’s Marketing and Development Coordinator for Oil Country Tubular Goods (OCTG) Grades, a senior expert with experience with material design, rolling and heat-treatment process, and material selection advisor for OCTG pipes in downhole conditions. The webcast attracted more than 230 participants from the oil and gas industry.

What is sour service?

Sour service refers to oil and gas exploration and production environments that have enough hydrogen sulfide (H2S) gas to crack metallic materials. Hydrogen sulfide is highly flammable and explosive; it is deadly even at very low concentrations. Sour service is one of the toughest challenges in hydrocarbon production, and due to a recent dip in oil prices, well operators are now looking for even more cost-effective solutions that combine high-strength steels and resistance to sulfide stress cracking.

High stakes, big challenge

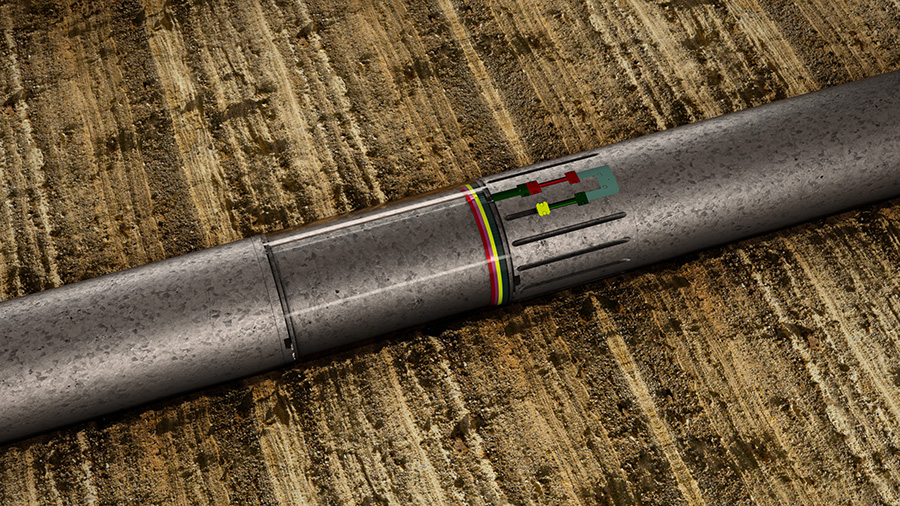

“Within the numerous difficulties faced by companies in the oil and gas industries, sour service operations remain among the most challenging,” explained Jonathas Oliveira. “When facing a reservoir with significant H2S content, well equipment requires a specific metallurgy to avoid critical failure. OCTG casing strings, which are not expected to have long term contact with production fluids, must be sour service resistant as they are designed as second barrier in case of tubular leak and SSC failure develops very quickly – in some hours.”

“There are three parameters to take into account when treating a sour field. The first is environment: temperature, the presence of acid gas, well pressures, and reservoir water composition. Then there are expected stresses, which define the required resistance in terms of internal and external pressures. Finally, there is the material itself and the mechanical and corrosion properties needed for an optimized well design,” he added.

An offer to meet every need

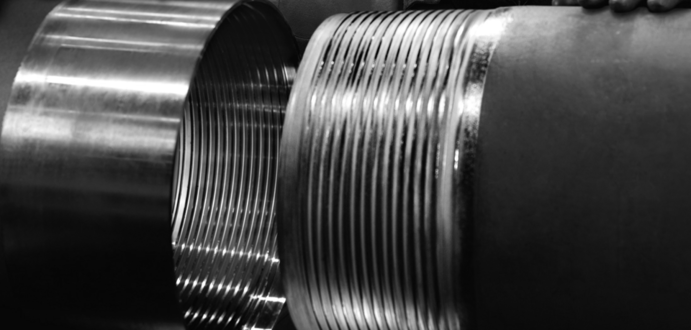

Vallourec’s expertise in material science, pipe production technology, and corrosion combine to create an offer that is perfectly adapted to this high-stakes challenge. Whatever the level of difficulty of the well environment, Vallourec has a tubular offer in high-strength sour service grades to meet the need.

We offer sour service-grade tubes for all OCTG applications, from conventional wells to high pressure and high temperature (HPHT), deepwater and unconventional wells, and have recently added innovative new solutions to our portfolio.

- For conventional wells, Vallourec recommends the VM110MS and VM125SS solutions for mild sour conditions and the VM95SS and VM110XS for extreme sour conditions. These solutions present considerable advantages over standard API-C110: the VM110MS, for example, can generate a cost saving of up to 10%.

- HPHT wells require very high-strength materials with enhanced collapse and burst performance. For this, Vallourec has developed the VM125ESS grade that draws on an innovative alloying concept and features a new chemistry and heat-treatment designs.

- Deepwater wells usually have long lifecycles and complex architecture. For these, Vallourec offers the VM110MS, VM125SS and VM130MS solutions for mild sour conditions and the VM110XS and VM125ESS for extreme sour conditions.

- Unconventional wells are cost-driven projects that require excellent burst properties. To meet these challenges, Vallourec’s most appropriate solutions are the P110MS and P110RY for mild sour conditions and the VM110XS for more extreme sour conditions.

As a tube’s mechanical properties increase, it becomes more and more difficult to achieve enhanced sour service resistance. The latest metallurgical developments have enabled us to create a full range of sour service solutions suitable for all well conditions, and to propose powerful cost-effective solutions to overcome our clients’ challenges.

Keeping the technical dialog open with our customers…

At Vallourec, we are committed to staying in close contact with our clients and prospects, supporting them with our products and services. This webinar is part of a series designed to explore their technical challenges and explain how we can help overcome them.

If you missed out…

You can play recordings of our past webinars whenever you want. Simply click on one of the following links to access the topics that interest you: