Vallourec’s Delphy solution is a game changer for hydrogen storage

Vallourec is revolutionizing hydrogen storage with its innovative underground vertical system. The solution responds to a gap in the market for storage solutions for mid-range quantities of hydrogen. By combining Vallourec’s experience in hydrogen-resistant tubes and connections with a unique vertical design, Delphy holds the potential to revolutionize the hydrogen value chain.

As global efforts turn to reducing emissions, green hydrogen production is high on the global energy agenda. International initiatives like REPowerEU in Europe and the Inflation Reduction Act in the United States are targeting huge increases in green hydrogen production.

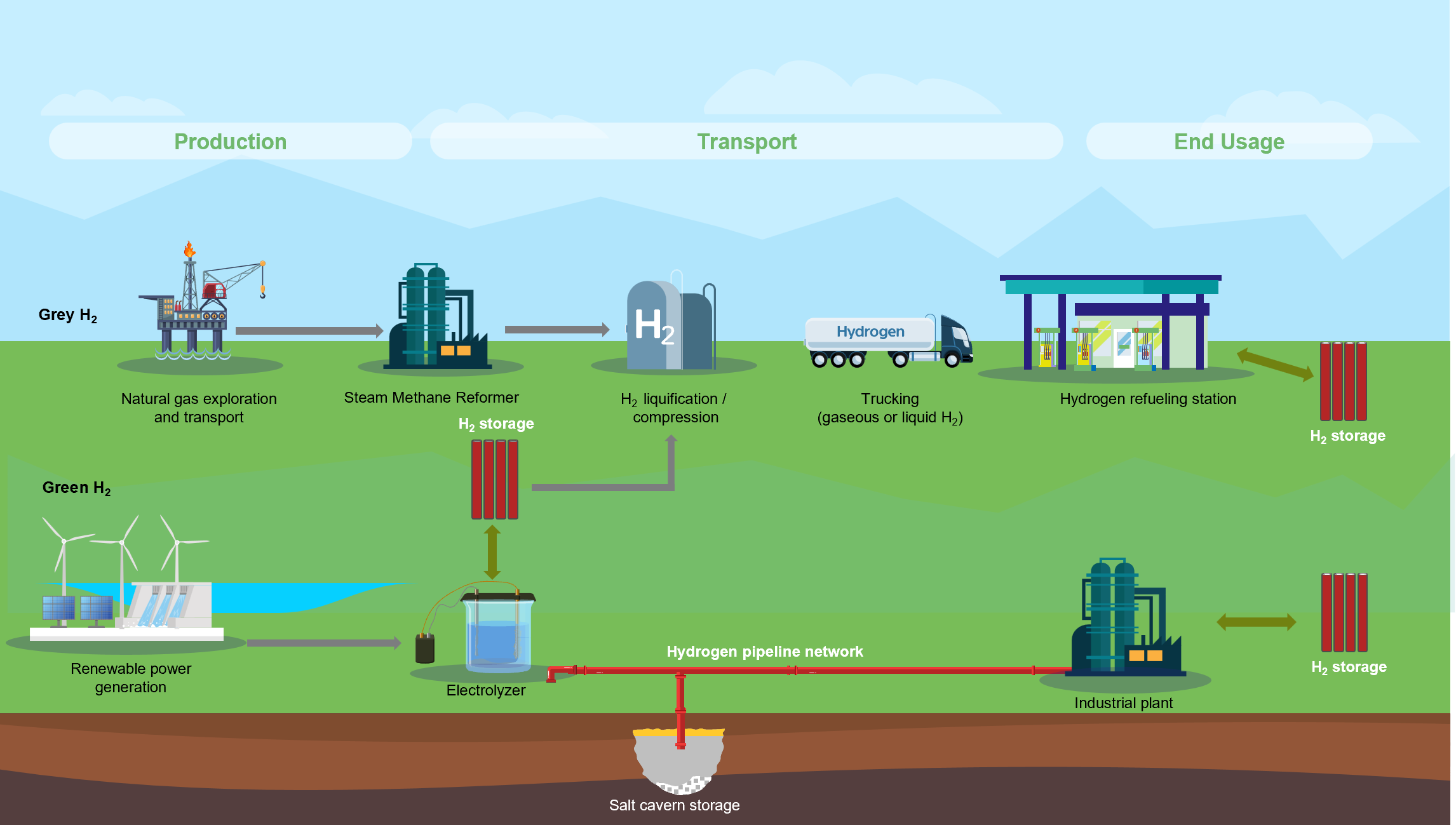

This marks a shift from traditional grey hydrogen, produced from natural gas. Green hydrogen – produced using electrolysis powered by renewable energies – is expected to account for the large majority of new hydrogen production coming online after 20251

This increased demand for green hydrogen inevitably comes with a need for storage solutions at every step of the value chain. Green hydrogen production is impacted by the intermittence of renewable energy, as well as varying electricity availability and costs. The solution is hydrogen storage, which both optimizes the electricity mix and improves the competitiveness of hydrogen production.

Transportation and distribution equally depend on storage solutions to respond to hydrogen requirements for heavy mobility. Downstream, industries like shipping, steelmaking and ammonia production depend on a consistent supply of hydrogen. Any interruption of production due to insufficient supply would have a severe impact in terms of process efficiency and cost.

The complexities of hydrogen storage

Hydrogen storage is certainly no simple feat. The top priority when envisaging storage solutions is safety.

Hydrogen is a highly flammable and explosive gas. It is difficult to contain, prone to leakage and can affect steel material through hydrogen embrittlement. Solutions must therefore be tailored to overcome these complex safety challenges.

On top of safety, hydrogen producers and users must consider permitting and acceptance. Current hydrogen storage solutions include overground cylinder racks which quickly become impractical when storing several metric tons of hydrogen due to the amount of physical space they occupy. They also become an eyesore when located close to communities.

The alternative to cylinder racks is geological storage in salt caverns or depleted gas reservoirs. This however depends on access to the suitable geology and pipelines and can take between five and seven years to construct. This type of storage also only lends itself to very large capacities in thousands of metric tons of hydrogen, which won’t be suitable for all needs.

Introducing Delphy

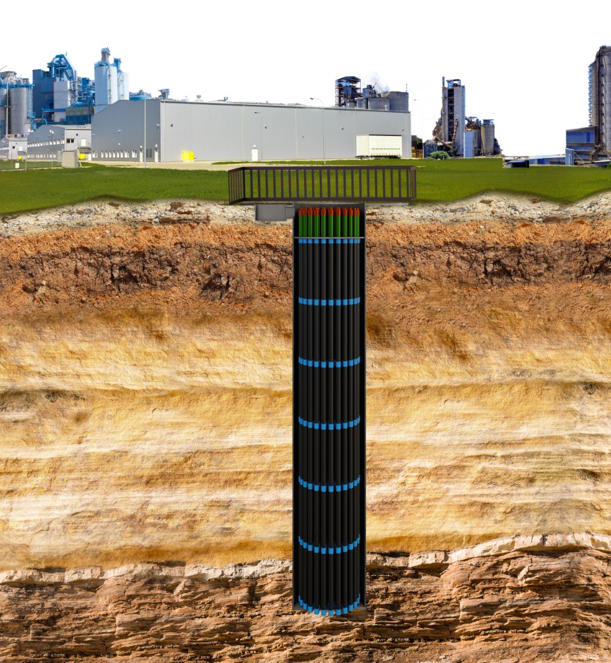

Conscious of the limitations of existing hydrogen storage solutions, Vallourec’s teams devised the Delphy system. Delphy can store between 1 and 100 metric tons of hydrogen on its site of production or use. It functions using a series of long pressure vessels, made out of pipe assemblies in which pressurized hydrogen is injected to be stored. Pipe strings are housed underground in excavated cavities between 5 and 10 meters in diameter and up to 100 meters deep.

Unique benefits

- Firstly, Delphy significantly reduces the footprint required for hydrogen storage – using up to 30 times less surface area than above-surface solutions. Located underground, the storage system is near invisible. This helps not only with acceptance from local communities and permitting, but improves security since hydrogen is much less exposed.

- Delphy also ensures optimal safety thanks to its vertical design. The cavity is inert, and with no oxygen between pipes, there is no potential for explosion. The system is equipped with passive ventilation, state-of-the-art leak detection, fire detection and fire safety, with materials explicitly engineered and validated for hydrogen applications.

- The underground vertical solution is modular and customizable. The number of strings connected can be tailored to storage capacity needs. The system is also scalable. If storage demand increases or decreases, tubes can be added or removed to adapt to the required capacity. This helps optimize both initial capital expenditure (capex) and operational expenditure (opex).

Innovation in action

To showcase the technology, Vallourec built a fully functional demonstrator of its Delphy system at its production site in Aulnoye-Aymeries, France. Inaugurated in December 2023, the site provides the opportunity to test the technology in real-world conditions, working with small scale hydrogen storage of around 150kg.

The demonstrator is home to a comprehensive testing program to approve and qualify the technology. Vallourec teams tested pressure to ensure containment tubes were safe and fully hydrogen-tight, and continue to conduct other tests including maintenance and emergency shutdown scenarios.

We are conducting in-depth tests at our demonstrator in Aulnoye-Aymeries until the third quarter of 2024. Once tests have been finalized, the site will become a training hub for Vallourec employees to gain experience in operational conditions and complete certification programs. Potential customers interested in Delphy can also come and see the solution for themselves.

The Delphy solution combines an innovative approach with Vallourec’s established hydrogen solutions. Proprietary steel grade was selected for excellent resistance to high corrosion and hydrogen embrittlement. Delphy also relies on Vallourec’s premium mechanical connections, leveraging its proven VAM® expertise for high performance to ensure optimal hydrogen tightness.

A promising future

Our customers and prospects confirm the necessity of a solution like Delphy to optimize their projects through hydrogen storage. Now ready to enter the market, Delphy is set to rapidly implement its solution in new hydrogen projects at industrial scale by 2025.

As a testimony of the commercial interest its garnered, Vallourec has already signed two partnerships related to the Delphy hydrogen storage solution.

The first is with H2V – a large-scale hydrogen producer in France and Europe. The collaboration will look at integrating Delphy in green hydrogen production and use projects to streamline costs, ensure reliable supply and be more flexible in production.

The second partnership with NextChem Tech is aimed at introducing Delphy into green hydrogen and green ammonia projects. The collaboration will focus on synergies between world-leading green ammonia production technologies and high-capacity hydrogen storage.

These partnerships are just the beginning for our Delphy solution, which promises to be a gamechanger for hydrogen storage at every step of the value chain. Word is spreading in the industry about our new solution, and we are analyzing an increasing number of projects to see how Delphy can bring value to customers.