Vallourec’s Pre-Installed Cable Protectors: Enhancing Rig Efficiency and Safety

On June 22, 2023, Vallourec conducted a live webcast focusing on its innovative Pre-Installed Cable Protectors (PICPs). Jon Bibby, Business Development Manager for PICP, presented the technology and its benefits. He showcased how Vallourec’s expertise in tubular solutions brings added safety and operational efficiency to well completion activities.

“The way we designed our PICPs is unique. They can handle the same load as the coupling, and we have tested them to withstand 25 kilometers of drag along the inside of a casing string without any damage or compromise to functionality,” said Jon.

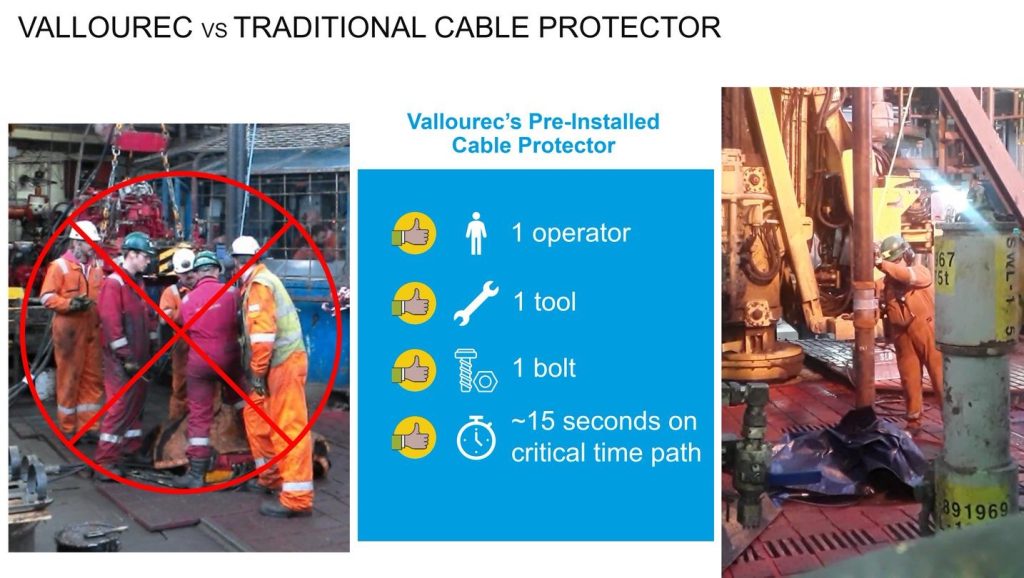

Enhancing rig safety: traditional cable protectors vs. PICPs

Traditional cable protector installations:

- Typically, cable protectors are installed on the rig floor as part of the RIH process. This requires multiple operators working in the red zone, which increases accident risk.

- Operators must manually lift and maneuver the cable protectors around the coupling while managing and capturing the cables. This poses safety risks and can lead to dropped objects.

- Multiple tools and steps are involved, such as pushing the cable parallel to the tube, wrapping collars around the tubing and tightening nuts and bolts. This further extends the critical time path and delays other RIH activities.

- Cable protectors are shipped in numerous heavy and cumbersome crates to the well site, requiring additional logistics and lifting operations on the rig floor. This further contributes to delays and potential safety hazards.

Vallourec PICP installations:

- PICPs are pre-installed offline during the rig prep process, away from the rig floor. This significantly reduces rig floor activity and minimizes personnel exposure in the red zone.

- PICPs are designed for easy and efficient cable insertion with just one operator and a single hand tool – a calibrated torque wrench.

- The installation process is simplified, requiring fewer steps and tools. Each cable protector can be fully energized in approximately 15 seconds, compared to an average of one or two minutes with traditional methods. Therefore a completion involving 400 joints could translate into savings of more than six hours in rig time.

- Since PICPs are pre-installed, there is no need to ship heavy crates of cable protectors to the well site or lift them on the rig floor. This eliminates logistical challenges and potential safety risks associated with crate handling.

Designing and testing PICPs for optimal performance

Vallourec takes a robust and systematic approach to developing PICPs, ensuring that each product can effectively withstand the demands of complex well operations. Using Equinor’s comprehensive TR2385 protocol, Vallourec subjects its PICPs to a range of rigorous mechanical tests, validating their functionality and durability under extreme conditions.

“We perform load-bearing tests that prove the weight-bearing capability of our cable protectors,” Jon said. “Then, we conduct wear tests that demonstrate their resilience over extensive distances. This is how we ensure that every aspect of our product meets the highest standards. And our protectors have shown excellent performance in the cable grip and hang-up tests. That verifies their capacity to grip and support cables effectively and safely, and to easily overcome obstacles in the wellbore.”

Customizing PICP solutions: Vallourec’s commitment to customer service

PICPs are not only designed to withstand demanding physical challenges but are also adaptable to varying operational requirements. Currently, their designs cater to tubing sizes of 3½”, 4½” and 5½” and can accommodate one or two cables of 11x11mm construction or a dual flat pack.

However, the quest for innovative solutions doesn’t end there. “We recognize the diverse needs of our clients,” Jon said. “This is why we’re currently developing new PICP designs for alternative cable configurations, and other tubing sizes and weights.”

Understanding the industry’s trend towards smart completions with higher cable and control line counts, Vallourec is innovating its PICP range to accommodate more lines.

“We’re working on new designs that can accommodate five or six lines, or even more,” he said. “These new models are also pre-installed, offering the same load rating as the coupling, which can significantly reduce red zone activity.”

PICPs can also be developed for non-VAM® couplings and premium tubing.

Operational benefits and cost savings

With Vallourec’s PICPs, the combination of time savings, improved operational efficiency and enhanced safety leads to significant cost savings. Less time on the rig means lower operational costs and faster well completions.

PICPs have been deployed in various well completions, demonstrating their effectiveness and delivering tangible benefits. Operators experienced a significant reduction in the number of personnel required in the red zone, eliminating the need for manual lifting and maneuvering of cable protectors.

“The reduced rig floor activity, single-operator insertion and simplified process resulted in faster completion operations,” Jon said. “This saves valuable rig time and minimizes potential risks.”

If you missed out…

You can read our dedicated new stories articles on our past webinars. Simply click on one of the following links to access the topics that interest you:

Webcast: Qualifying Vallourec’s Steel Pipes for Hydrogen Storage and Transportation (December 2022)