VAM® 21, guaranteeing the highest performance thanks to extensive testing

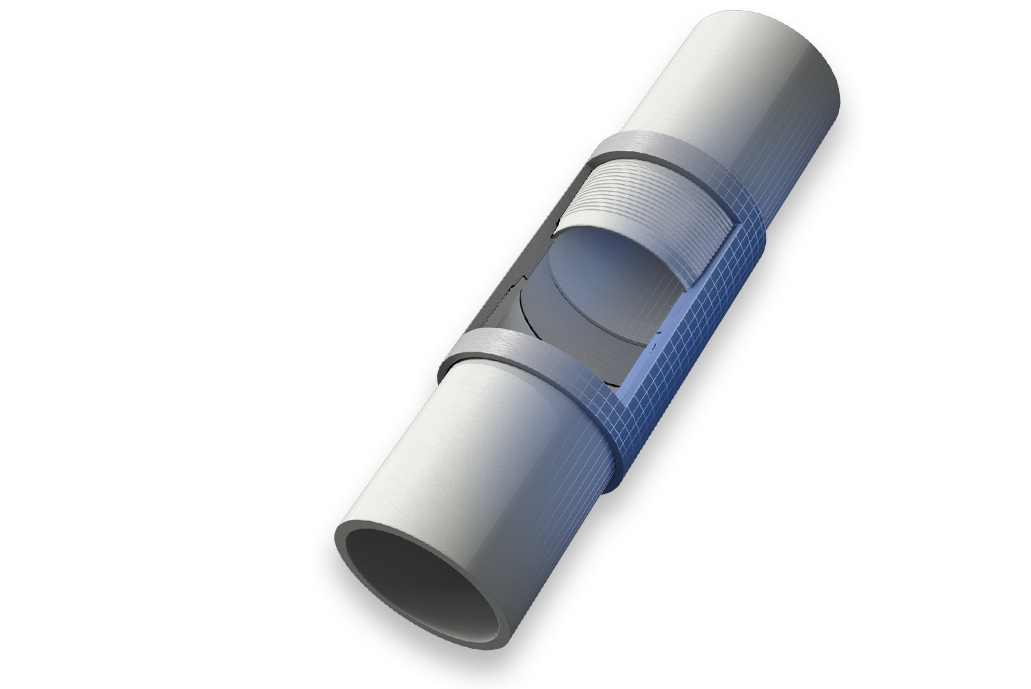

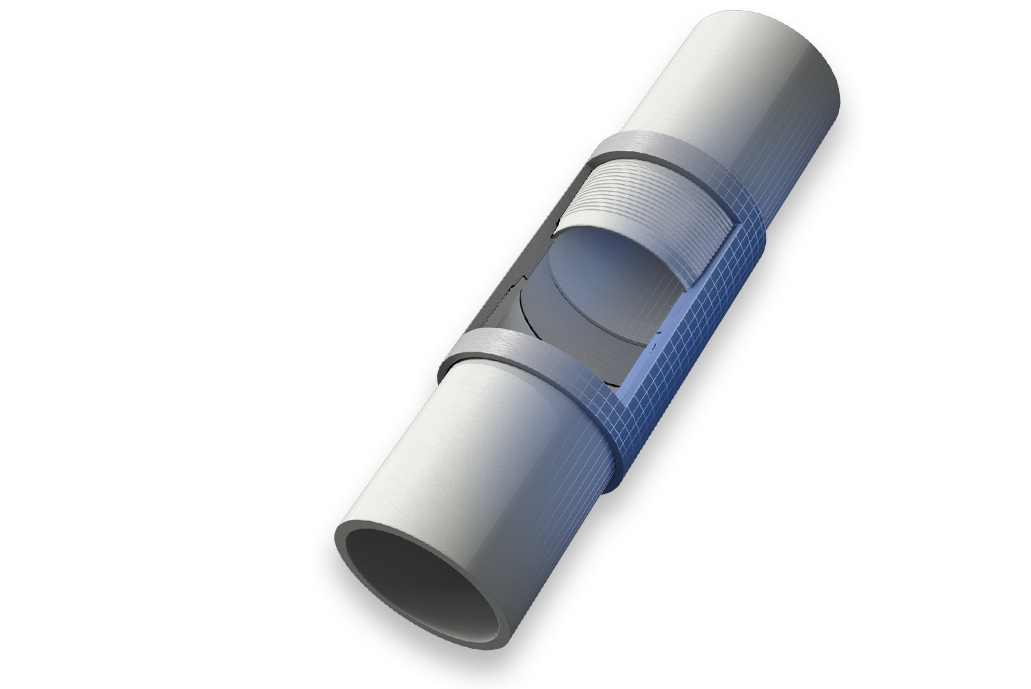

Since it came on the market, VAM® 21 has fast established itself as an industry favorite for a wide range of applications. Becoming the oil industry’s connection of choice the world over didn’t happen without reason. Besides providing strong performance results, the entire VAM® 21 product line has also been extensively validated according to the most stringent test protocols including API RP 5C5:2017 CAL-IV and beyond, thus meeting customers’ strict requirements across all applications.

Vallourec’s extensive and trustworthy qualification protocols have long been recognized and appreciated by customers worldwide. With technical validations now being required by all operators, VAM® 21 has a head start in offering its customers thorough testing results and qualifications no matter the application, including the most critical such as HP/HT, High Collapse and High Torque.

Wading through HP/HT waters

As the most demanding environment, High Pressure/High Temperature (HP/HT) wells require robust connections for complex well architectures that must handle pressures up to 20,000 psi and temperatures of 180°C (356°F) and above. VAM® 21 was tested to high temperatures of up to 240°C (464°F) meeting the requirements of even the most demanding environments such as those found in the North Sea which are operated by clients who are under some of the strictest national regulations.

These tests were performed according to API RP 5C5:2017 CAL-IV testing protocol and were also adapted to specific customer requirements including bottom hole temperature and failure tests consistent with the most severe well loads.

Our customer TotalEnergies in the North Sea who operates HPHT wells (West Franklin and Elgin Franklin wells) with bottom hole temperatures of up to 215°C (419°F), turned to VAM® 21 for their projects. For this critical application, both the customer and the local authorities require that every single piece of equipment fitted in the well be proven as fit-for-purpose. This is especially important for production tubing and production casing which are key components in ensuring well integrity–respectively part of the primary and secondary envelope of the well.

For this application, Vallourec ran dedicated connection qualification testing on connections 5½” 26.80# VM 25 125 VAM® 21 (CRA) and 10” 73.90# VM 140CY VAM® 21. The testing sequence applied was agreed upon with the customer’s drilling and completion teams to ensure full coverage of the most severe well loads (internal/external pressure as well as compression loads) and the most extreme temperatures (above 180°C/356°F, beyond API RP 5C5:2017 CAL-IV requirements). Additionally, TotalEnergies carried out specific tests on samples provided by Vallourec involving external pressure with gas at elevated temperatures.

VAM® 21’s extensive testing provided TotalEnergies with the reliability and integrity they needed for their HPHT wells. Since the testing was successfully completed, VAM® 21 products have been ran in over ten TotalEnergies HPHT wells.

For more information on a similar HPHT project, read the 2018 Offshore Technology Conference technical paper.

Withstanding the pressure of High Collapse

High Collapse (HC) pressure, the term given to external pressure beyond standards, is typical of critical wells due to depth, formation loads or temperature. Vallourec provides a series of High Collapse and High Strength proprietary grades capable of withstanding these high external pressures–and VAM® 21 is up to par.

A full program of advanced tests was rolled out to validate VAM® 21’s performance on High Collapse pipes mainly on ODs 7’’ to 13’’5/8. To meet the criteria, the connections’ external pressure was increased between 10% to 40% of a standard API 5CT pipe maximum pressure value required (depending on size) to match the HC pipe body performance. VAM® 21 is therefore as strong as the HC pipes with regards to external pressure loads allowing well design to be based on the HC pipe body’s true performance.

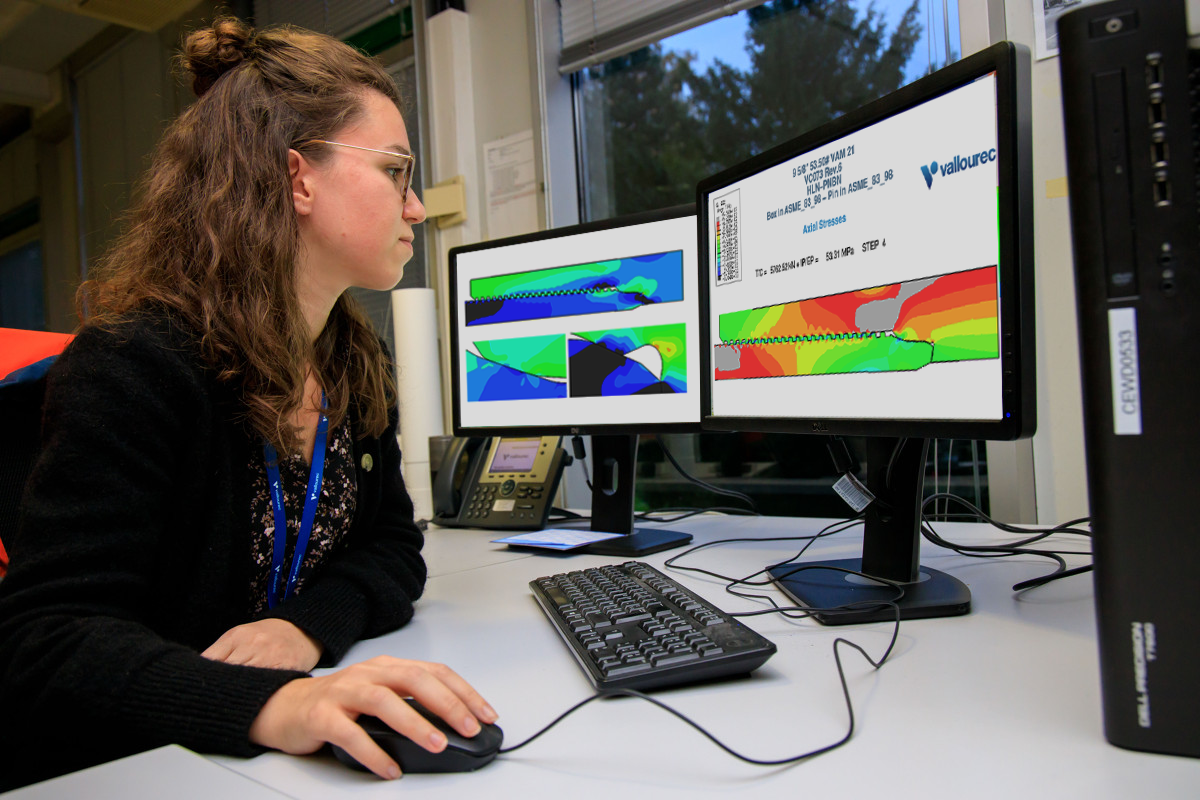

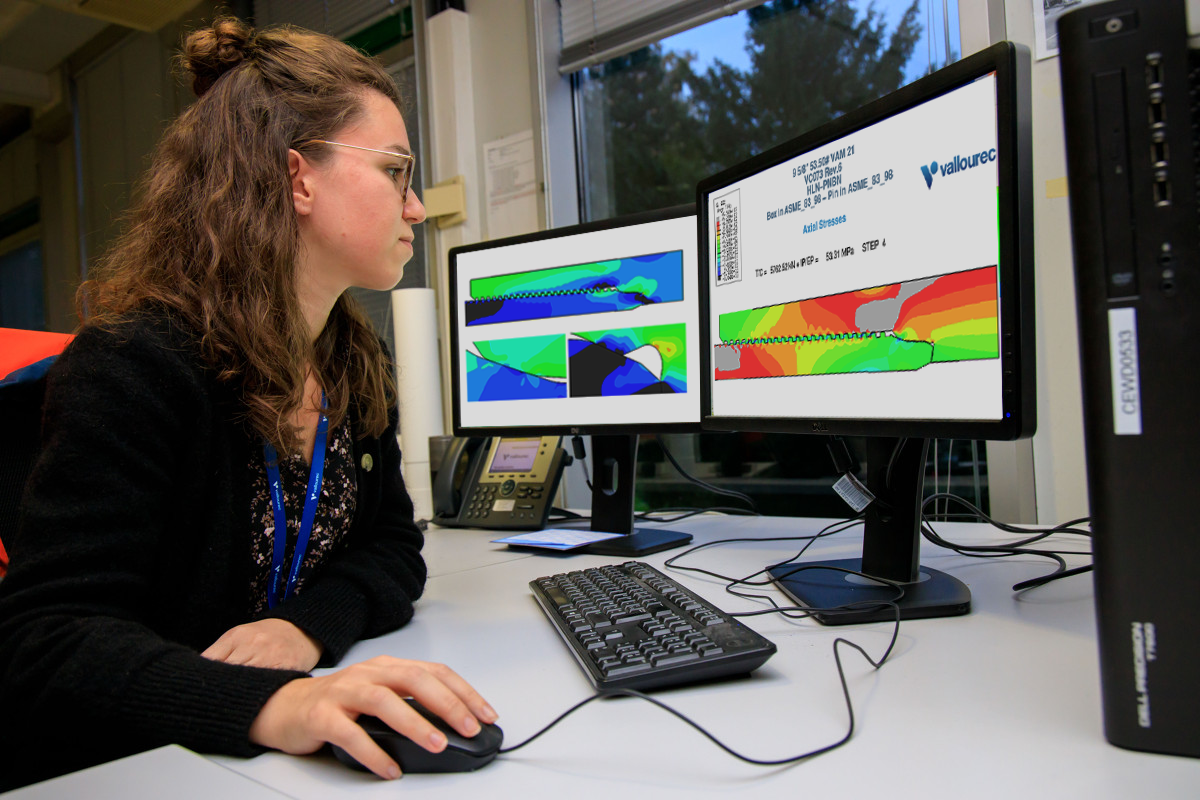

In addition, physical tests were conducted on critical sizes which were then combined with FEA (Finite Elemental Analysis) extrapolation on standard sizes (up to the High Collapse value of the pipe) in order to cover the full product range. Thanks to this extensive testing, Vallourec counts with a comprehensive test database proving the High Collapse performances across the entire VAM® 21 product line.

VAM® 21 has become the standard for key customers in Brazil’s pre-salt wells thanks to its high performances especially when combined with High Collapse pipes.

In one instance, one of these customers needed to reach reservoirs found under a 2,000-meter-thick layer of salt. The Brazilian Pre-Salt rock behaves as a thermo-viscoelastic material that has a tendency to creep when subjected to stress. The viscosity of the salt rock is responsible for wellbore closure after a certain time creating difficulties for well construction, especially for casing. In order to counteract this technical difficulty, the use of pipes with enhanced resistance to collapse was vital as well as the development of premium connections with heavy wall pipes to withstand the collapse loads exerted by the thick salt layer–all while maintaining structural and sealing integrity.

In addition to these challenges, the customer also needed to optimize well production, requiring specific tubing and casing sizes fitted with enhanced Coupling Outside Diameters (Special Clearance) that met the well’s clearance specifications.

Vallourec developed and validated the following specific casing and liner sizes in order to meet both the special clearance requirements and connection sealability at the “High Collapse” rating of the pipes:

• Intermediate casing in 13 5/8” 88.20# VM 110 HCSS VAM® 21 NB-SC80

• Intermediate casing in 14” 114.00# VM 110 HCSS VAM® 21

• Production casing in 10 ¾” 85.30# VM 110 HCSS VAM® 21 HW NA SC70

• Production Casing in 10 ¾” 65.70# VM 110HCSS VAM® 21

• Production casing in 10 ¾” 73.20# VM 110 HCSS VAM® 21

• Production Casing in 9 7/8” 66.90# VM 125 HCSS VAM® 21

• Liner in 7” 32.00# VM 125 HC

For more information on this project, read the 2018 Rio Oil & Gas technical paper.

Guaranteeing maximum sealability under High Torque

When installing a liner in a well, the pipe string needs to be rotated requiring the use of High Torque connections to prevent leaks from occurring and to ensure the string’s integrity. Multiple tests were conducted to validate VAM® 21’s sealability when High Torque is applied on the pipe string as per API RP 5C5:2017 / ISO 13679:2019 CAL-IV. These tests were carried out on connections made up at the MTS (Maximum Torque with Sealability) value and their bending resistance has been validated up to 42°/100 ft.

In addition, VAM® 21 HT (High Torque) was designed and validated at MTS to offer even more torque for the most demanding applications such as rotating liners or drilling with casing (ERD, multilateral wells and horizontal sections) and is completely compatible with the standard VAM® 21 design.

VAM® 21 HT was recently supplied to a customer in the Middle East who operates Extended Reach Drilling wells (ERD) of up to 8,500 meters at true depth (TD) with up to 6,500 meters of horizontal sections. For this application, the liner (6,500-meter long) needed to be rotated during installation and cementing and was therefore subject to high torque loads. The customer’s drilling team concluded that a torque of 14,500 ft.lb was required. The 7” 23.00# L80 VAM® 21 HT was selected for this application as its Maximum Torque with Sealability (MTS) of 14,950 ft.lb met the operational requirement.

Meeting low-carbon application requirements

VAM® 21 has now gone beyond standard applications to meet the requirements needed for geothermal wells and hydrogen underground storage. The connection provides even the most critical geothermal wells with full compression capacity and is qualified up to 350°C under thermal cycles following the TWCCEP testing standard. In addition, VAM® 21 has been successfully tested with 100% hydrogen and cyclic loading, providing customers with a fit-for-purpose qualification protocol for hydrogen storage wells pending a dedicated industry standard.

Find out more about the qualification of VAM® 21 for hydrogen testing.

A large range of tested and proven connections

Boasting a wide range of dimensions and a variety of grades, VAM® 21 is the most versatile and easy-to-use connection suitable for a wide range of configurations – from standard wells to the most complex operations. With multiple test results according to strict protocols and physical tests carried out on critical sizes depending on the application, VAM® 21 is one of the most qualified and reliable connections on the market today, offering its customers a comprehensive technical offer with proof of its safety and performance across its entire product line.

Key points to consider when it comes to Premium Connection testing

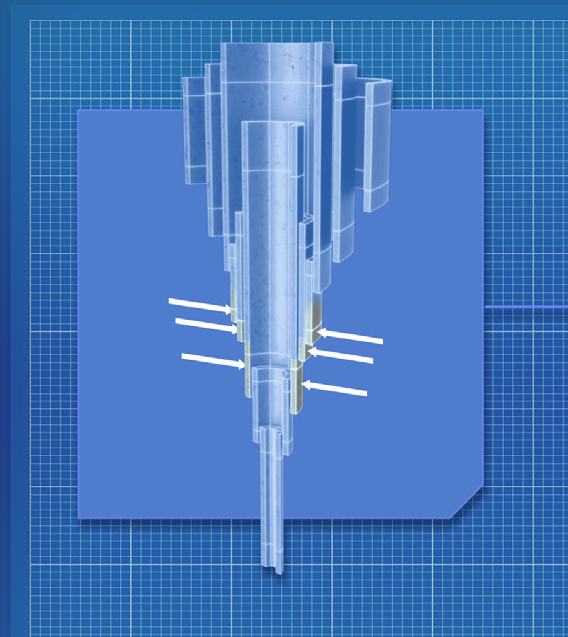

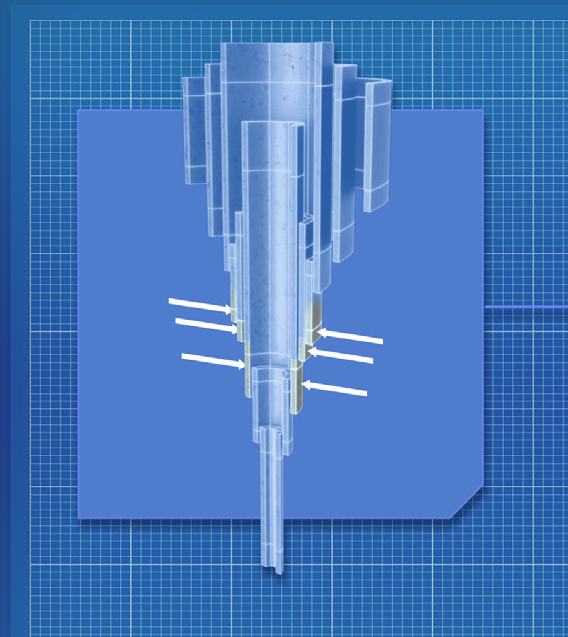

The main purpose of Premium Connection testing for the operator is to demonstrate the suitability of the connections with the expected well-loads during the entire life of the well.

In case of critical applications, the operator needs therefore to ensure that the connection passed successfully the most severe industry protocols (currently API RP 5C5:2017 CAL-IV) and consistently with the expected well loads.

Key points:

- The % level of the loading applied on the connection VME ellipse (e.g. 95% IP/EP/Compression loads in the Serie A at ambient temperature) (2)

- The envelope of performance claimed, shall be completely tested on each sample at each extreme load points promoted,

- In the case of High Collapse (HC) pipes, the calculation of the “collapse loads” in Q3 and Q4 shall be based on the collapse rating of the HC pipe body and not API 5C3 collapse rating. (3)