VAM® LOX: Growing Track Record in Offshore Operations

VAM® LOX: Growing Track Record in Offshore Operations

31/05/2021 – OCTG

Since its launch in 2018, VAM® LOX has obtained an important track record in surface casing operations, gaining the confidence of offshore operators around the world. Its latest successful runs in Malaysia and Trinidad and Tobago strengthen its position in the market as a cost-efficient, high-performing alternative to weld-on connectors.

Meeting new market requirements

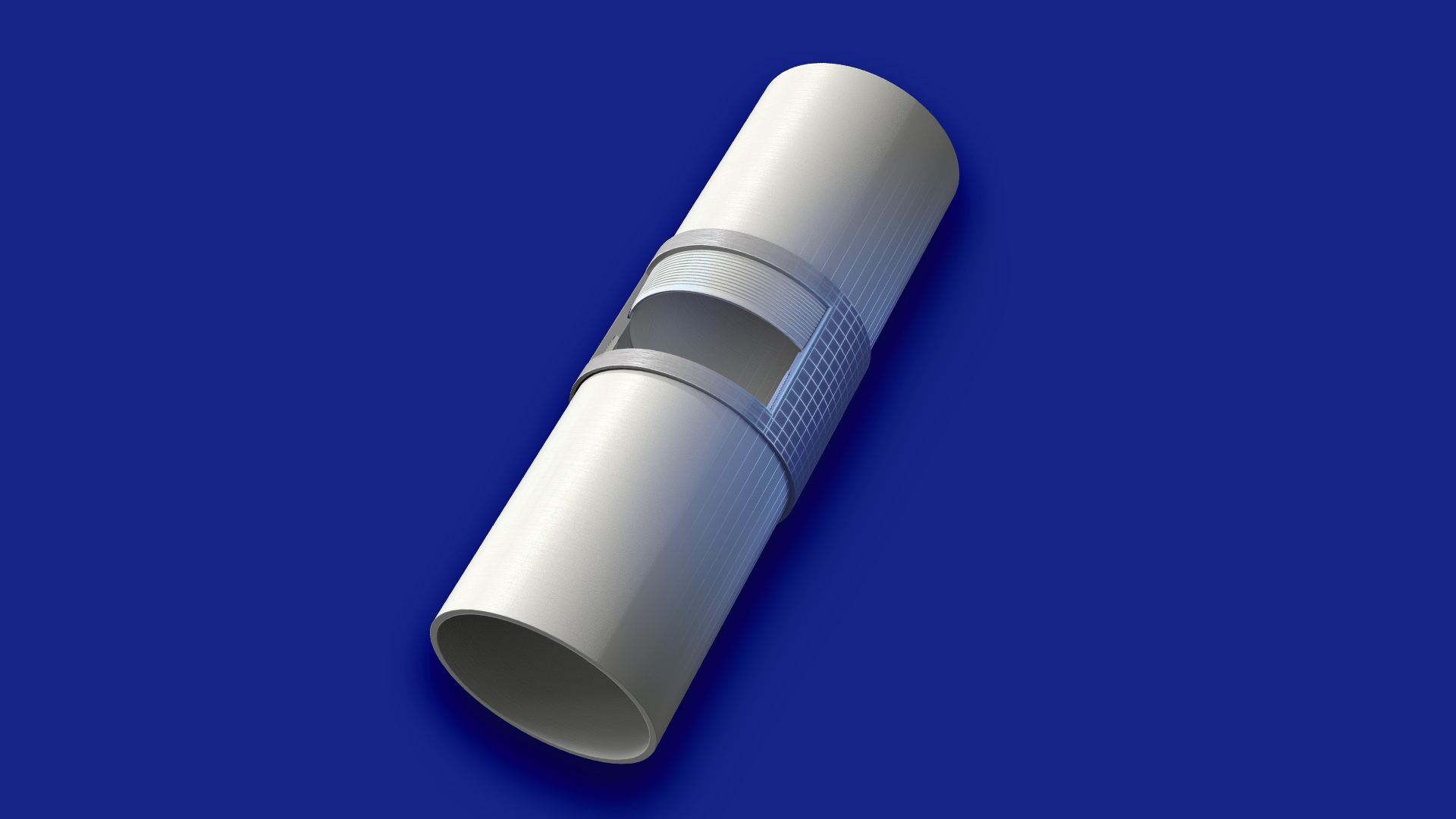

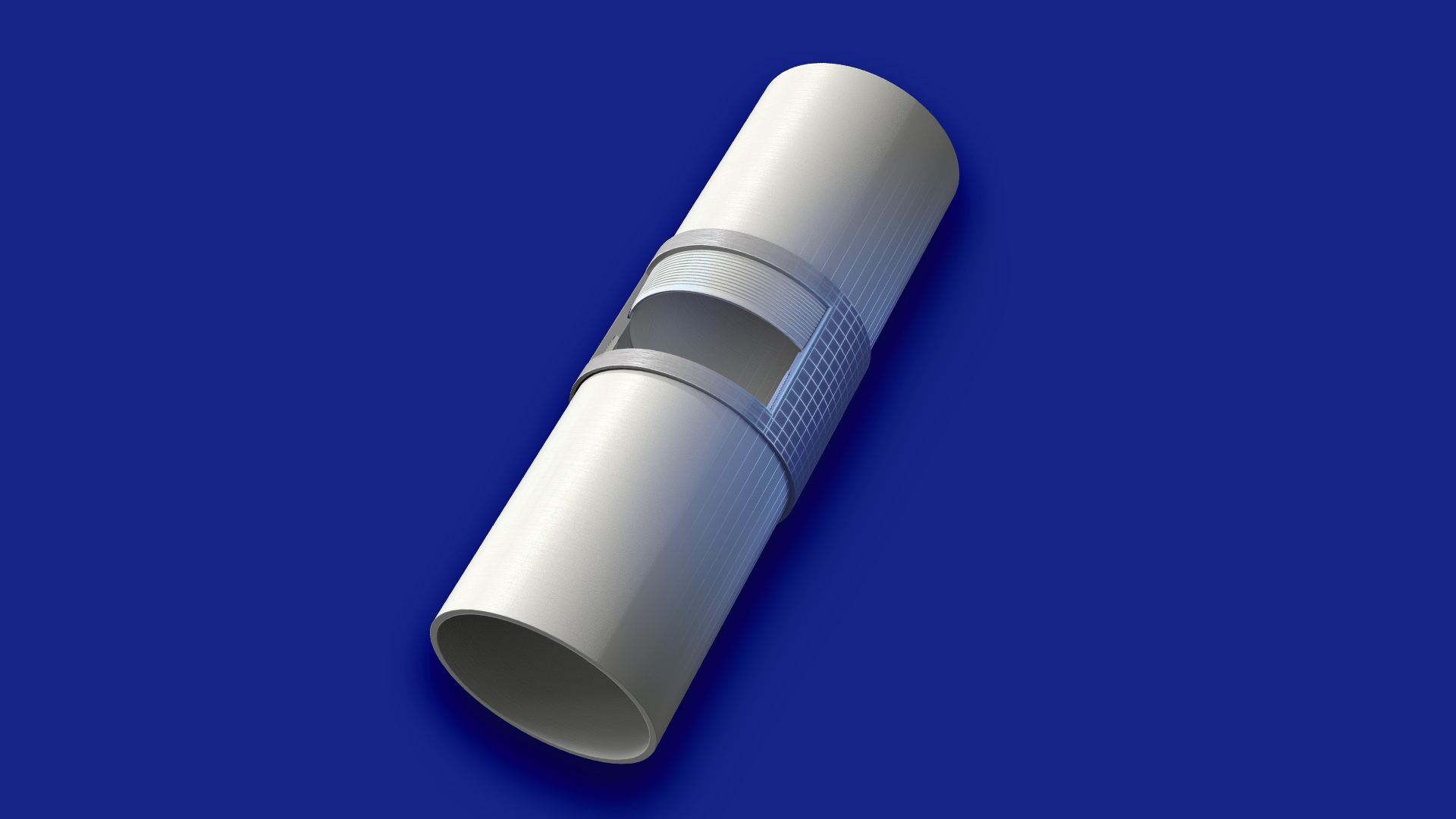

VAM® LOX is a premium surface casing connection designed to meet high performance needs, providing gas tightness, structural integrity and easy running operations.

Surface casing is a crucial step in the construction of an offshore well. It is the initial casing set that is installed in a well which acts as an important structure to host other casing strings inside and may have a blowout preventer (BOP) attached to its top. Because surface casings are very large (between 18” and 20” in OD), they are heavier and more difficult to handle on the rig floor and misalignment can often occur during stabbing.

Traditionally, weld-on connectors are more widely used to build surface casing strings, but this means higher costs for operators, and with offshore exploration taking place in deeper and more complex environments, cost efficiency has become a must.

To meet these challenges, VAM® LOX, a threaded and coupled connection, eliminates the need for welding operations and features a lighter design for better clearance and easier handling on the rig. In addition, deep stabbing and double-start threads allow for fast and reliable running thus allowing operators to save time and costs.

Its design enables the use of high-strength grades up to 125 ksi and provides 100% Pipe Body Yield Strength resistance in tension and compression and 100% ISO 10400/API TR 5C3 collapse resistance.

A growing track record

Since its successful first running in Bolivia back in November 2018, VAM® LOX has performed consistently in open sea running conditions including in HP/HT wells of up to 12,000 psi and 150°C (302°F).

Two additional offshore runs recently performed to the North-West of Miri (Malaysia) and on the East coast of Trinidad and Tobago (Caribbean Sea), add 4,000 meters (13,000 ft) to VAM® LOX’s existing field track record.

In both cases, customers were looking for connections validated to the most stringent protocols, including the API 5C5:2017 CAL-I (Gas) qualification level which VAM® LOX’s metal-to-metal internal seal provides. The connection was supplied in ODs of 18 5/8” and 20” with carbon steel pipes up to 110 ksi that allowed for lighter string designs and better clearance. Sets of VAM® LOX accessories were delivered to complete the package.

With no rejects or back-out operations due to connection cross-threading or other issues, customers were very satisfied with VAM® LOX’s performance.

“Thanks to VAM® LOX, we not only start with a very good foundation for the following drilling stages, but we also manage to save costs without compromising on performance”, states an offshore operator. “This is crucial, as the whole well integrity and safety depends on it”. Both operators also found invaluable the strong technical support and the supply chain reactivity provided by Vallourec which were key elements in the success of their operations.

Opening the way to more runs

Additional offshore running jobs with VAM® LOX are planned in the coming months in East Africa and in South East Asia. Thanks to this growing successful track record in onshore and offshore applications, VAM® LOX surface casing connection is positioning itself as a high-performing and cost-efficient alternative to weld-on connectors worldwide.