VAM® SLIJ-3 for HP/HT ultra-deepwater projects

With reservoir pressures beyond 15,000 psi, equipment manufacturers are being challenged to design specific products for these complex wells, including new pipe dimensions, accessories and connections.

VAM® SLIJ-3, discover our new connection

Improving performances on market-known solutions

Since VAM® SLIJ-3 was specifically designed with the requirements of 20K projects in mind, it is the perfect fit for complex well architectures that must handle pressures up to 20,000 psi and temperatures up to 350°F (175°C).

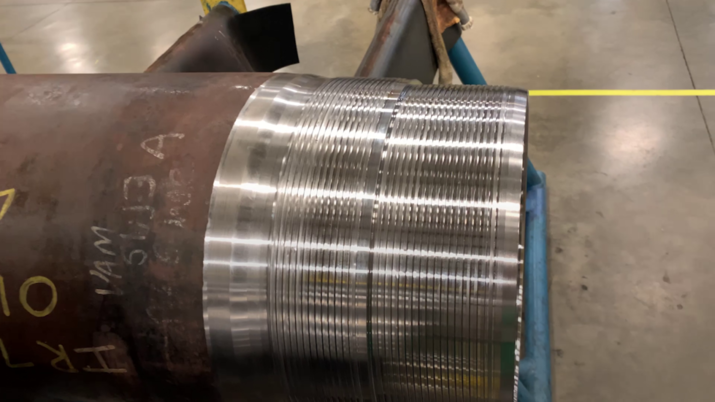

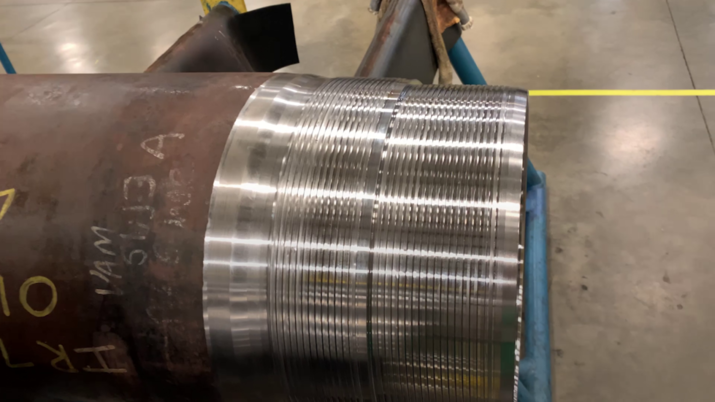

VAM® SLIJ-3 builds on decades of field experience and expertise gained with VAM SLIJ-II, widely recognized as an industry reference. Thanks to optimized design features, VAM® SLIJ-3 pushes the limits by offering a larger performance envelope, higher tension and compression strength and greater torque capacity, while still allowing for clearance.

The new product brings superior performance in critical offshore environments, together with improved make-up ability. It was validated in priority on high-performance grades, including high collapse and sour service, such as Q125 HC, VM 125 HCSS, VM 130 MS or VM 140 CYHC. The result is the best-in-class semi-flush connection, fully validated to the latest industry standard on high-end, high-performance pipe grades.

A combination of winning features

“The VAM® SLIJ-3 design is qualified to a larger envelope than what was previously available and has passed the latest and most stringent testing programs in the industry – such as API RP 5C5: 2017 CAL-IV,” explains Alan Fothergill, the Product’s Lead Engineer and Designer. “We’ve improved the thread design so it’s better for deep-stabbing and smooth make-up, has better galling resistance, and can withstand higher axial loads.”

“From the very start of development, we used latest generation pipes that have extremely high collapse performance, which meant that by design the connection had to fulfill very high external pressure resistance and be suitable for use in critical environments,” adds Céline Schès, Vallourec’s VAM® SLIJ-3 Project Manager.

A pragmatic approach to product development

The idea for VAM® SLIJ-3 was first explored several years ago, when expert teams were working to identify new concepts for the next generation of semi-flush products. “Our approach was very pragmatic,” explains Daly Daly, Vallourec’s Senior Technical Sales Manager for offshore US operators, who worked on the product from the very beginning.

“One approach was to take existing solutions and build on them, boosting performance and adding the best design features from other best-in-class products, like VAM® 21. In the end, thanks to various enhanced features, we achieved a performance increase ranging from 20% to 40% compared to VAM® SLIJ-II. VAM® SLIJ-3’s service envelope is now the largest on the market” he says.

Putting the connection to the test

The involvement of clients in the development of new products is often crucial. In this case, some of the US oil industry’s biggest operators played a major role in the development of VAM® SLIJ-3.

“Having a target client from the beginning is a huge help,” explains Céline Schès. “We worked to develop a solution that would suit their needs and be as cost-effective as possible.”

“We performed tests on a rig with real-life offshore conditions,” adds Fothergill. “The 14” and 16.08” VAM® SLIJ-3 were tested with double and triple stands using a fit for purpose testing protocol and found to be fast, easy and robust.”

Looking to the future