VAM® SLIJ-3 premium connections successfully validated for hydrogen applications

Vallourec’s R&D team based at the Vallourec Research Center in Aulnoye-Aymeries (France) recently conducted a series of rigorous tests on VAM® SLIJ-3 connections with CLEANWELL® for hydrogen storage applications. Now validated up to 16” diameter for use in underground salt caverns as well as for Vallourec’s Delphy solution, VAM® SLIJ-3 enhances the Vallourec® New Energies portfolio.

With the growth of hydrogen as an alternative energy, renewables providers are increasingly using salt caverns for storage. “We observed a trend toward wider-capacity wells, which allow for faster leaching of new caverns,” says Harold Evin, CCS & Hydrogen Director. “And, once such a well is operational, hydrogen can be injected and withdrawn much more quickly.” This necessitates larger diameters of pipe that can still withstand incredible pressure and wide temperature variations.

“Until now, our VAM® 21 13 3/8” premium connections were the maximum diameter we’d qualified for use in hydrogen storage,” says Justine Bernard, Vallourec Hydrogen Storage Technical Manager. “Our new goal was to qualify our VAM® SLIJ-3 connections up to 16” for use in salt caverns, as well as with our Delphy hydrogen storage system.”

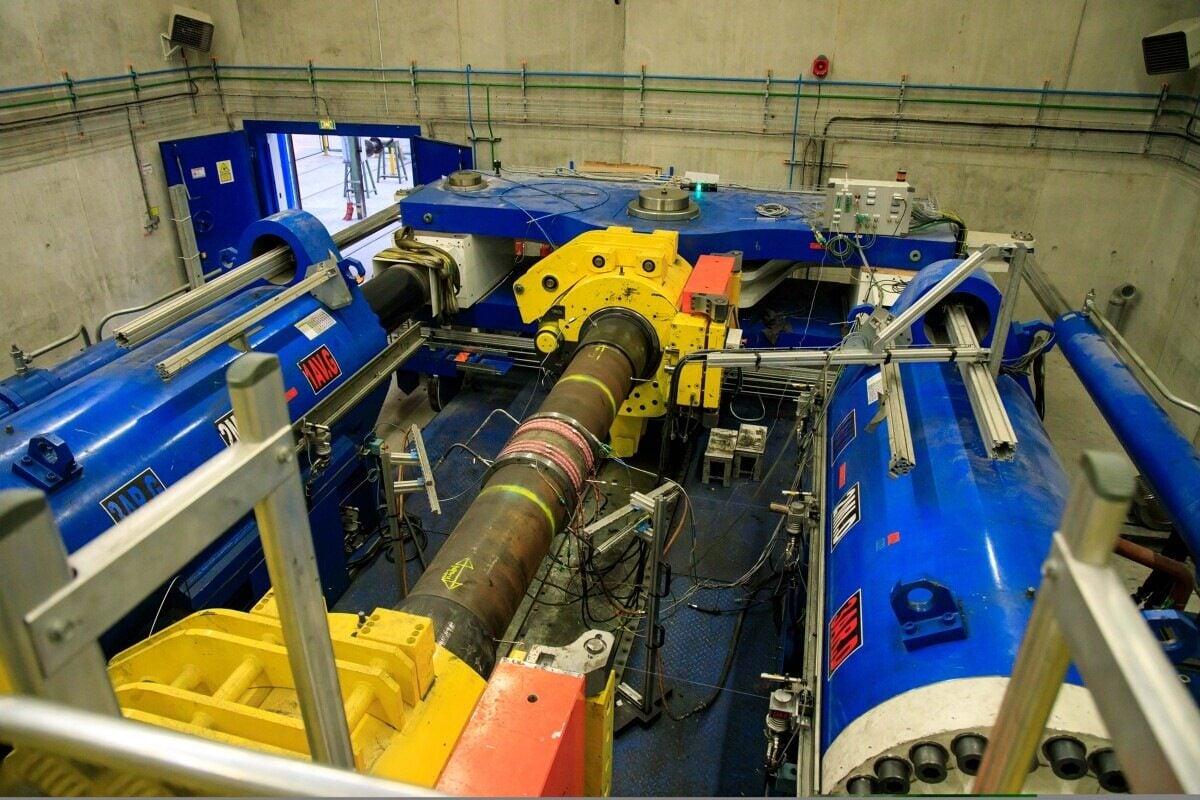

Setting up the test

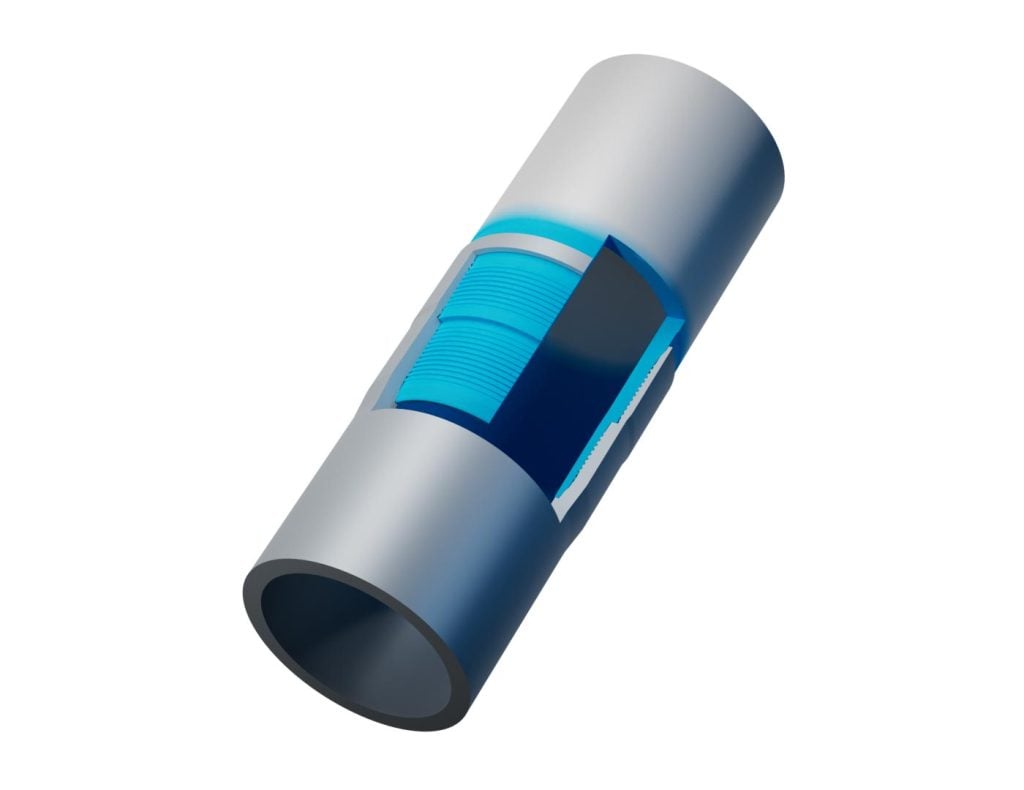

VAM® SLIJ-3 is the latest generation of premium flush connections that Vallourec offers. It provides high performance alongside a slim design. “It’s adapted for the most critical conditions and has become a staple in high-temperature/high-pressure wells in the Gulf of Mexico for several years now,” says Ayoub Mansouri, R&D Engineer at Vallourec. “However, hydrogen storage applications require an entirely different set of protocols, and that means stringent testing parameters.”

Due to the hydrogen molecule’s small size, the challenge is to ensure that connections are tight enough to hinder leakage regardless of the environmental conditions they face onsite. “We set up advanced protocols at our testing facility in terms of temperature, pressure cycles, compression and more,” Ayoub says.

The primary objective for testing at the facility is to cover every possible scenario that pipe connections might face in their real-world applications.

We’ll always try and push the boundaries when we evaluate the performance of our premium connections in situations where our products might be used. We have very advanced testing benches, and, in fact, we want to test beyond what will be found in operational environments. If it doesn’t leak in the mill, it won’t leak in the field.

Taking testing to another level

The connections were tested over five key phases:

Phase 1, the longest testing phase, involved over 10,000 internal pressure cycles between 450 and 500 bar, and carried out at 5% hydrogen / 95% nitrogen.

Phase 2 focused on temperature and internal pressure variations representing seasonal variations of storage. It put the connections through tests from 4° C—the lowest temperature achievable in a saline cavity—to 180° C. This phase proved challenging, as it required the team to adapt its methods and equipment to reach the desired temperatures in an adequate cycle time to conduct

Phase 3 made a bending assessment, testing the connection at the limits of the Von Mises envelope for tension and compression under a bending stress.

Phase 4 involved a sealability check conducted at maximum internal pressure (749 bar), up to 95% of the pipe’s yield strength.

Phase 5 provided the opportunity to conduct a pure hydrogen check at 100% hydrogen internal pressure and 475 bar. This last phase confirmed representativity of the tests carried out with 5% hydrogen / 95% nitrogen mixture and provided final validation that the combined stresses from phases 1 to 4 did not compromise the connection’s performance. For this final check, Vallourec partnered with third party external lab CETIM in Nantes (France).

CLEANWELL® offers next-generation connection coating

VAM® SLIJ-3 was qualified for hydrogen applications using CLEANWELL®. Applied to the surface of VAM® SLIJ-3 and other VAM® connections at Vallourec mills, CLEANWELL® is a non-polluting, multi-function coating. It replaces both storage and running compounds, providing outstanding anti-corrosion and lubrication properties.

“It’s key to our New Energies applications,” Harold says. “It’s cleaner and more reliable than dope and provides exemplary performance with regards to tightness, which is so important for hydrogen storage and for use with our Delphy solution.”

Obtaining successful results

The final verdict: the VAM® SLIJ-3 connection is well suited to extreme conditions in terms of pressure, temperature, sealability and bending. “Whether in a salt cavern or in Delphy, you need to respond to high pressure needs, and make sure the connection is tight,” Vincent Designolle, Delphy Director says. “VAM® SLIJ-3 is exceeding our goals.”

Regarding tightness, no hydrogen leakage was detected through the five phases of testing. Sealability was validated according to API RP 5C5: 2017 leak detection standards calibrated with hydrogen. For phase 5 at 100% hydrogen, the estimated leak flow rate was 5.03*10-08 mbar L/s. “This is well below the threshold,” Ayoub explains, “and much lower than the API standard.”

VAM® premium connections are already used in most salt cavern projects in Europe, and this latest testing success builds on Vallourec’s technological edge.

It means being able to bring the right products to our customers’ most difficult projects, adapting to their needs and keeping at the forefront of testing programs. And the same goes for Delphy. Our ability to manufacture these premium pipe connections is critical in assembling our Delphy systems.

Leveraging the knowhow of Vallourec’s R&D teams has been crucial to the test’s success. As it continues to develop its Vallourec® New Energies portfolio, the Group will look to its experts to continue to adapt solutions that support its customers’ goals.