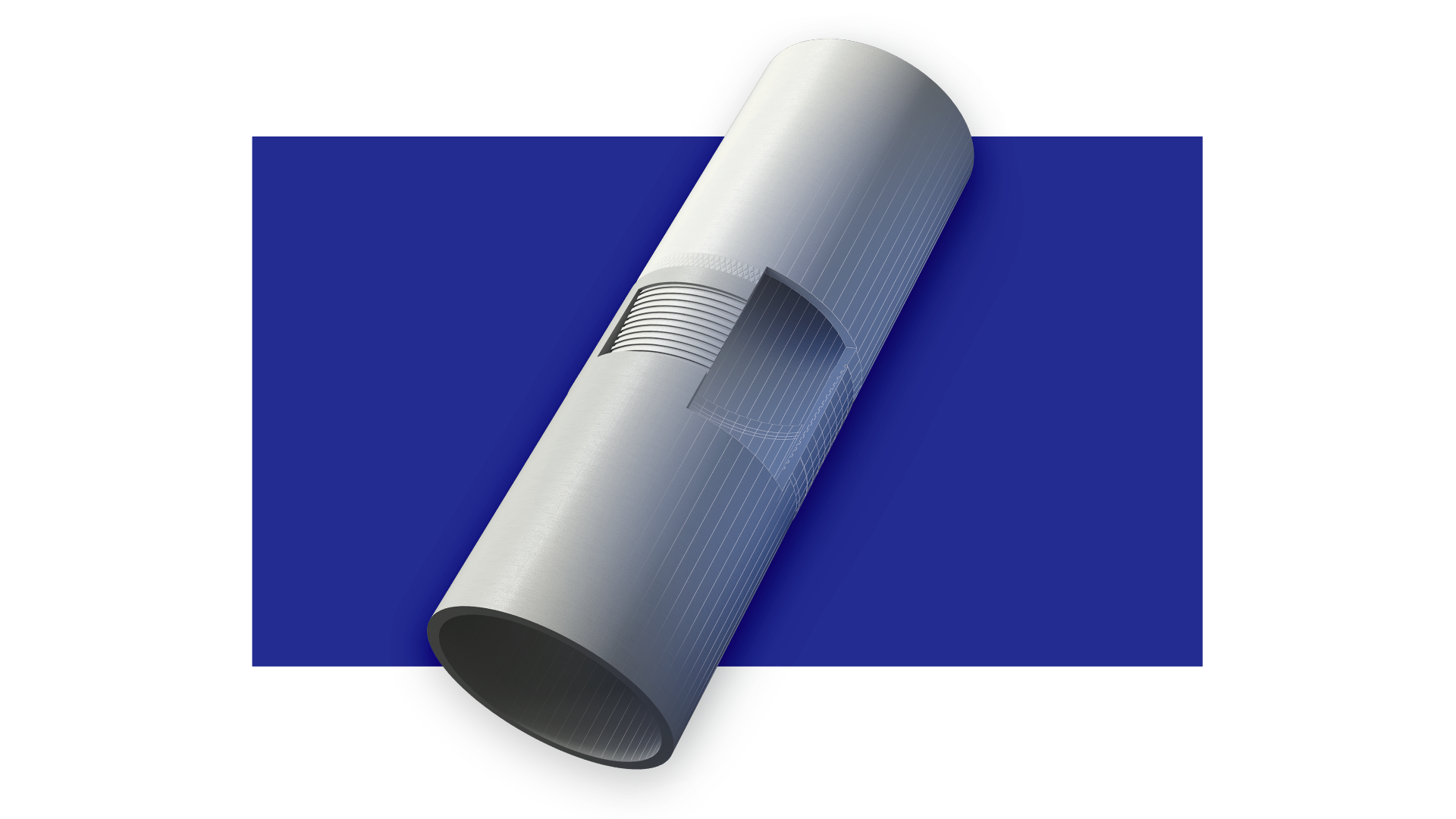

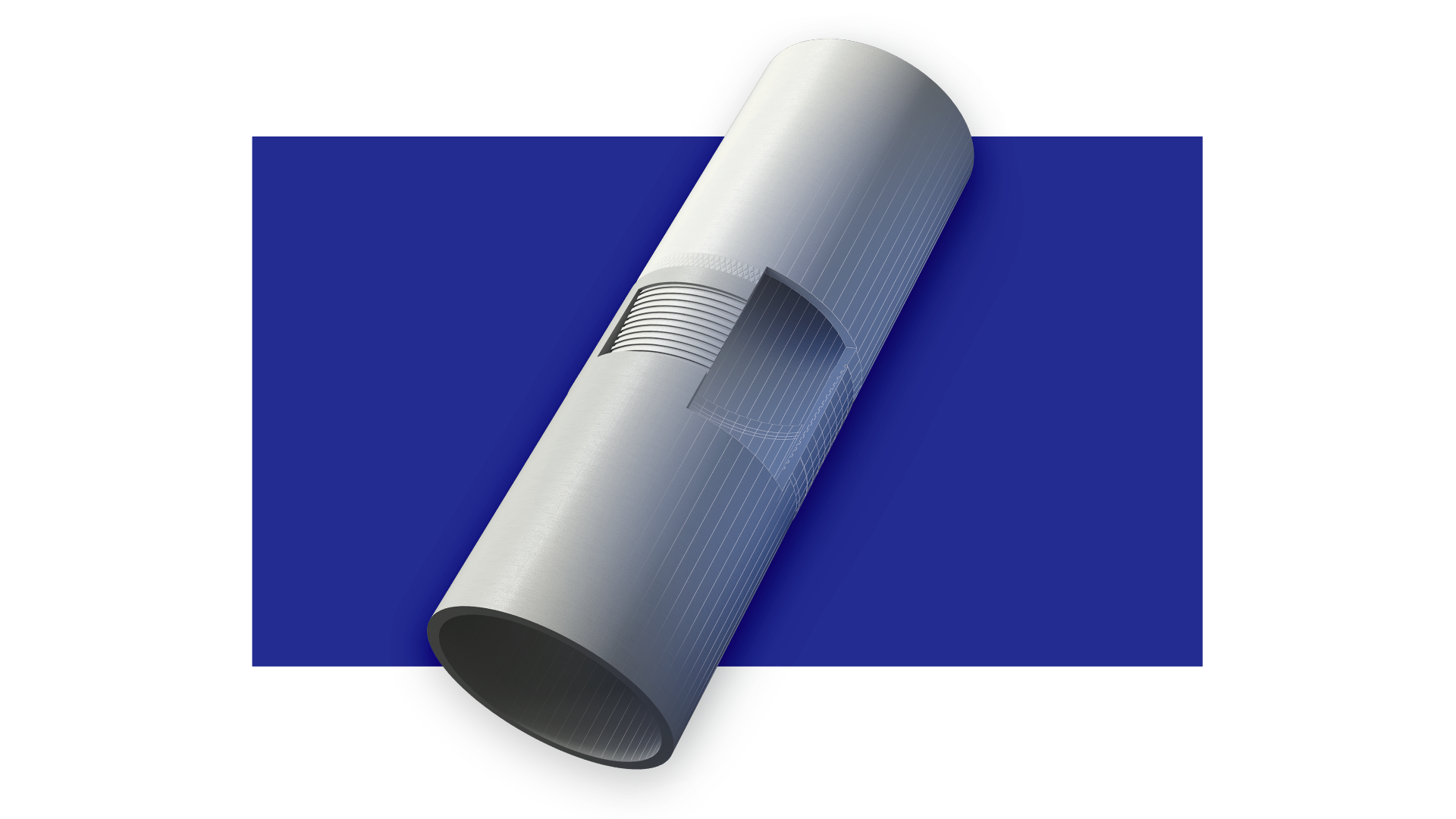

VAM® SPRINT-FJ for High Tension and Maximum Clearance in Intermediate Strings

Increased casing requirements for wells drilled on federal lands drove the widespread use of flush integral connections in the western portion of the Permian shale region. But as wells were drilled deeper and longer, the tension requirements grew beyond what existing connection technology could provide. VAM® SPRINT-FJ was developed to cover this higher technical specification while maintaining the cost competitiveness of semi-premium connections to fit the onshore unconventional market. During its first run, a West Texas operator set a nearly 12,000 ft long 8-5/8”’ 32# intermediate string using VAM® SPRINT-FJ top to bottom.

Meeting challenging tensile load requirements

The New Mexico side of the Delaware Basin in the Permian, which is in part managed by the Bureau of Land Management, requires wells to have an additional intermediate casing string. This is an effort to provide enhanced protection of surrounding geological formations and aquifers. Furthermore, it is required there be sufficient space in the annulus for thorough cementing of those strings. The resulting four-string well designs face significant challenges with connection selection. As operators started drilling deeper and extending laterals to increase production efficiency, the existing integral connections available could not meet the tensile load requirements. Operators in the Permian brought up a need for a flush connection, meaning the same diameter as pipe body, for intermediate casing sizes that could handle higher tension loads but remain cost-effective for a region dominated by basic API and semi-premium products.

This operator wanted to run 8-5/8” 32# casing with flush connections inside 10 ¾” casing. The connections available in the market, both premium and semi-premium, didn’t have the high tension required to set intermediate casings deep enough in the formation. To set the string at about 12,000 ft in depth and accommodate operator’s casing design safety factors for flush connections, the tension rating required was at least 60%, compared with 50% or less in the existing flush connections in the market at the time.

This previously forced operators to use T&C API connections at the top of the string to get the higher tension capacity. The only other option was to buy reputable domestic plain end pipe from one manufacturer and then thread a connection on it that did not have a mill source and was not optimized for its own seamless pipe. Both options added increased complexity to logistics, supply routes, and budgets. Pursuing a higher quality thread design with its own premium seamless mill source created a one-stop solution with better performance, cost, and logistics.

Designing VAM® SPRINT-FJ specifically for intermediate string applications

VAM USA worked to design a cost-effective flush connection that would get up to 80% in tension capacity on some target sizes, which pushed design limits and exceeded the performance of existing connections on the market. While developing several initial design concepts, R&D and industrialization engineers collaborated in order to streamline production to avoid design features that might lead to higher cycle times and cost.

Operators worked in partnership with Vallourec and VAM® providing valuable casing design data, feedback on testing protocols required, and additional features that could be added to the development. This allowed us to add extra benefits in a timely manner such as further testing with limited gas pressures, pressure testing with bending at 10 deg/100ft, knurl markings for ease of make up in the field, make up and operational torque ranges that would meet but not exceed the needs of the market and equipment.

VAM® SPRINT-FJ was officially launched in November 2020. The first run was completed in May of 2021, in the Delaware Basin. The casing was set at 11,800 ft up to surface. The operator expressed satisfaction with the high running efficiency at about 25 joints per hour, thanks to 4.9 turns to make up, compared with the incumbent connection’s 6-7 turns to make up.

For this first run, torque-turn monitoring was utilized, and the knurl marks on the pins were used for an added visual make up indicator. Each make up was validated by the VAM® Field Service Technicians on site monitoring the run. The first run didn’t see any difficulties that would present a need for high rotational torque to get to depth but with an operational torque capacity upwards of 48,000 ft.lbs, there is plenty of room for additional torque should conditions necessitate.

The operator and distributor also praised the one-stop solution, combining Vallourec pipe and threads. This adds value by simplifying the supply chain while also having pipe specifications and thread development controlled by the same high-quality standards.

To date, this operator has run nearly 5,000 joints of VAM® SPRINT-FJ and continues to utilize it on multiple rigs.

Overview of results

• Max clearance: <0.5% over pipe OD

• High tension capacity: up to 80% PBYS

• Fast running: 4.9 turns to make up

• High operational torque: 48,000 ft.lb.

• Knurl marks for visual make-up indicator.

• Local licensee available in West Texas.

• One-stop solution, combining pipe and thread from a single vendor for optimal quality and cost.

• Confidence to set casing into the bend, pressure tested with bending at 10°/100ft.